3 homemade PVC pipes

After repairs, PVC pipes may remain, which can be put to good use by making a few simple homemade projects. When heated, polyvinyl chloride becomes plastic, so working with it is a pleasure. For the manufacture of the proposed homemade products, only pipes will be used without the use of other materials.

Ice tongs

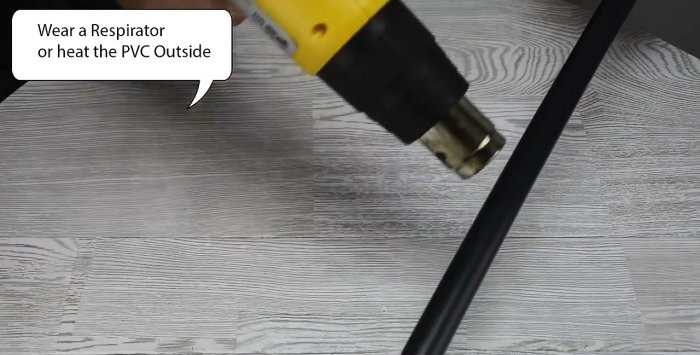

A section of PVC pipe is heated along its entire length with a heat gun.

As soon as it becomes plastic, it must be compressed with a wooden block, giving the tube a flat shape.

The center of the flattened workpiece is heated with a hairdryer, and it is bent in half around another whole pipe.

To strengthen the workpiece, you need to squeeze out the stiffening ribs on it. To do this, the halves are heated one by one, and then pressed lengthwise with a tube of smaller diameter.

The ends of the workpiece are heated and compressed with a clamp to solder the walls, making them flat.

Existing defects can be corrected with sandpaper, and the pliers can be used for their intended purpose.

They made great tongs for ice or something else.

Modification of screwdriver handles

Old or inconvenient screwdriver handles can be covered with PVC pipes on top. This makes them thicker and longer, so they fit better in your hands.

A small piece of tube, approximately 5-7 cm, is heated with a hairdryer and partially pressed onto the handle of a screwdriver.

As soon as it hardens, you need to warm up its protruding end and put on the plastic plug.

It is important that it does not stick, so it must be constantly rotated until it cools completely. Now, resting your palm on the plug, you can twist the screwdriver without rubbing the skin.

If you heat up the PVC tee remaining after the repair and place it on the handle, you will get a convenient removable T-shaped handle for screwing in and unscrewing fasteners under load.

Keychain mini cutter

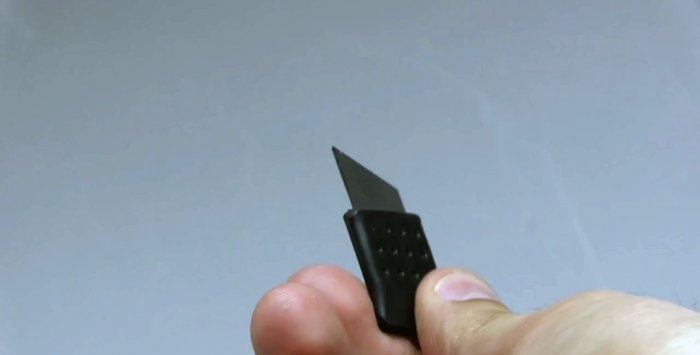

To make a miniature keychain knife, you need to cut off a piece of tube about 3-4 cm. Squeezing it with clamps, insert the blade of a mounting knife into it, after which the workpiece is clamped to the maximum.

After reheating the workpiece, you need to compress it again, placing a needle plate between it and the jaws of the clamp. You only need to press in half of the tube from the blade side.

The second part should be locally heated over a candle and soldered, compressed as much as possible with a clamp.

Several segments are broken off from the blade so that the knife blade is not too long.

For the sheath, another piece of pipe is used.

It heats up, stretches over the blade with a handle and flattens.

The sheath is smoothed with sandpaper and attached to a carabiner from a keychain. Now the knife can be carried on keys.

If something happens, you can cut off even a thick seat belt if it is jammed.

Watch the video

Similar master classes

Particularly interesting

Comments (0)