How to make a UPPERLIG floor lamp like from IKEA and save money

Good afternoon I saw the UPPERLIG floor lamp in the IKEA store. I liked the lamp and considering how much it costs (about 4,000 rubles), I figured that I could make one myself for almost pennies. And I went to the nearest hardware store and bought the following...

First, let's make the “leg” of our lamp. To do this, take an aluminum tube and begin to bend it. It is important to choose the correct bend radius, otherwise we will end up with an ugly bend. The radius of 160 of the plug turned out to be small. But the 200 radius of the plug worked perfectly.

We take the tube and start bending it.

We make 3 through holes on both sides of the tube and screw screws into them.

We send the structure for painting

While the “leg” is drying, let’s move on to making the lampshade. We take a small plug for 160 and an LED lamp. We heat up the hot glue gun and go through all the joints of our lamp so that moisture does not get inside.

Next, we extend the wire from the lamp.

Take the plug and measure 18 mm.

Use a step drill to make a 14mm hole.

We cut out the wall so that we can then get the cast form.

Now let's put everything together.

We center the lamp and fix it with hot glue.

We insert the cut out wall and seal it with glue.

Pour in plaster. Add a little PVA glue to the plaster. When dry, it will add strength to the plaster.

Poured plaster. I remove the bubbles using an orbital sander.

We wait a day for the plaster to dry. The lampshade just didn’t want to come out. I had to cut the plug

The plaster flowed a little under the lamp.

Let's check if the lamp works? Or was it flooded with water?

Everything is fine! Let's continue! While the plaster is still elastic, we cut off everything unnecessary.

It turned out well.

Next we move on to making the base. The procedure is almost identical to making a lampshade. But there are a couple of differences.

We take the housing from the LED lamp driver and seal it.

We insert the wire into the driver housing. Fill everything with glue. We place a large plug inside and fill it with plaster.

We wait 2 days and try to get it. It doesn’t work without a saw, so we saw.

We take out the cover from the driver.

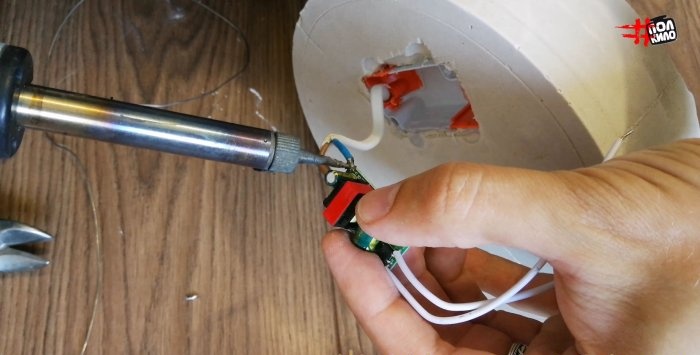

We take out the wire and solder the LED driver to it.

We insulate the wires with hot glue.

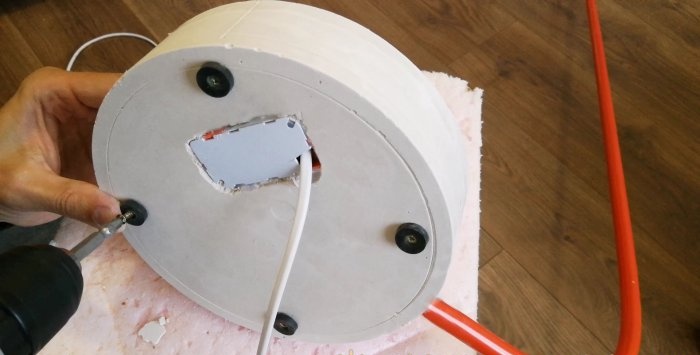

We put everything into the driver housing. Screw on the 4 rubber feet and the lamp is ready!

The lamp fits perfectly into my interior. It is convenient to read, work on the computer, or watch TV under it.

I hope you liked my homemade product!

More details can be found on my Youtube channel.

Will need

- Two sewer plugs with a diameter of 160 and 200 mm.

- Aluminum pipe with a diameter of 14 mm and a length of 2 m.

- LED lamp.

- Wire, plug and switch.

- Construction gypsum.

- PVA glue.

- Dye.

Manufacturing of the floor lamp UPPERLIG

First, let's make the “leg” of our lamp. To do this, take an aluminum tube and begin to bend it. It is important to choose the correct bend radius, otherwise we will end up with an ugly bend. The radius of 160 of the plug turned out to be small. But the 200 radius of the plug worked perfectly.

We take the tube and start bending it.

We make 3 through holes on both sides of the tube and screw screws into them.

We send the structure for painting

While the “leg” is drying, let’s move on to making the lampshade. We take a small plug for 160 and an LED lamp. We heat up the hot glue gun and go through all the joints of our lamp so that moisture does not get inside.

Next, we extend the wire from the lamp.

Take the plug and measure 18 mm.

Use a step drill to make a 14mm hole.

We cut out the wall so that we can then get the cast form.

Now let's put everything together.

We center the lamp and fix it with hot glue.

We insert the cut out wall and seal it with glue.

Pour in plaster. Add a little PVA glue to the plaster. When dry, it will add strength to the plaster.

Poured plaster. I remove the bubbles using an orbital sander.

We wait a day for the plaster to dry. The lampshade just didn’t want to come out. I had to cut the plug

The plaster flowed a little under the lamp.

Let's check if the lamp works? Or was it flooded with water?

Everything is fine! Let's continue! While the plaster is still elastic, we cut off everything unnecessary.

It turned out well.

Next we move on to making the base. The procedure is almost identical to making a lampshade. But there are a couple of differences.

We take the housing from the LED lamp driver and seal it.

We insert the wire into the driver housing. Fill everything with glue. We place a large plug inside and fill it with plaster.

We wait 2 days and try to get it. It doesn’t work without a saw, so we saw.

We take out the cover from the driver.

We take out the wire and solder the LED driver to it.

We insulate the wires with hot glue.

We put everything into the driver housing. Screw on the 4 rubber feet and the lamp is ready!

Enjoying the result

The lamp fits perfectly into my interior. It is convenient to read, work on the computer, or watch TV under it.

I hope you liked my homemade product!

Watch the video

More details can be found on my Youtube channel.

Similar master classes

Particularly interesting

Comments (0)