How to make a cool lounge chair with simple tools

Even in the absence of professional carpentry tools, you can make high-quality, beautiful and convenient furniture. One such example is a reclining chair. The lumber used to assemble its frame requires minimal processing, since in this design the main decorative accent is given to the soft cushion. At the same time, the rough frame looks very modern and is perfect for a home furnished in a loft style or for placement on an indoor track.

The frame of the chair will consist of 2 crosspieces made of wide edged boards, connected to each other by bars. The lumber used for its manufacture will retain saw marks, which will make the whole process much easier. But if you wish and have a thicknessing machine, the frame can be made perfectly smooth.You need to make 2 sidewalls from short and long boards intersecting at right angles. At the same time, at the ends of the boards that will be installed on the floor, corners are cut at 45 degrees.

At the intersection of the crosses, a sample is made on both boards so that when joining they are in the same plane. To do this, a cut is made on each of them to half the thickness, after which the wood is selected with a chisel and trimmed with a plane.

Also, on the edges of short boards, from the side where the legs are cut at 45 degrees, you need to select a quarter 250 mm wide for subsequent fastening of the jumper between the crosspieces.

Before connecting the crosspieces, you need to round off the upper ends of the boards. For short ones, the rounding is done on the inside of the chair, that is, diagonally from the cut corner of 45 degrees, and for long ones, on the same side. First, the required angle is cut, and then it is given a smooth bend with a plane.

After this, the prepared boards are coated with a sample of glue and folded into crosses.

Then, at the intersection, 4 holes are made for installing dowels. All protruding glue must be removed immediately. If you leave it, then the impregnation will not be absorbed into these places.

Next, the crosspieces are connected by a jumper made of boards. It is installed with the ends in the previously selected quarter. The board is secured on each side with glue, one self-tapping screw and a pair of dowels. The screw head is set 1 cm deep. Then its hole from above is clogged with a dowel.

On the back, the crosspieces are connected by three bars, which are also installed on screws and dowels. Two jumpers are placed in the center of the backrest with a small gap, and one on the edge at the headboard. Below at the intersection, the crosspieces are connected by a wide board.After this, the protruding parts of the dowels are cut off, the chair is sanded and impregnated.

Cover with varnish.

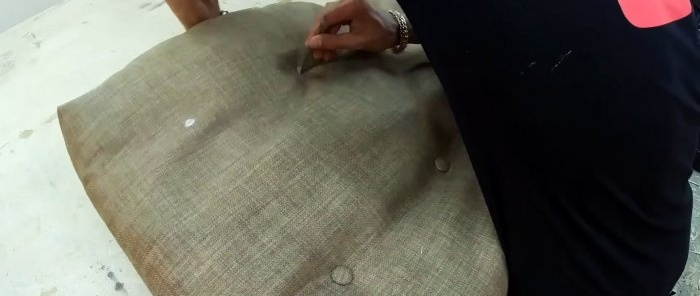

The base for the pillow is made from leather, burlap or other durable fabric. 2 pieces of material are cut out and stapled one by one onto the frame of the chair. One of them forms the seat, the second the backrest.

A bag with a zipper is sewn from the upholstery fabric. Its size is selected so that it fits completely on the seat and back. After this, the bag is filled with padding polyester. The resulting pillow is stitched and tightened with twine, to the ends of which furniture buttons are tied. This will make it more presentable and prevent the padding polyester from sticking to one edge.

The pillow is tied to the chair with twine.

You can also sew a small bag for him to store books, newspapers or a phone. It is nailed to the side of the chair.

Materials:

- edged board 30x250 mm;

- wooden dowels;

- block 50x50 mm;

- self-tapping screws;

- wood glue;

- tinting impregnation for wood;

- leather or burlap;

- upholstery fabric;

- padding polyester;

- furniture buttons;

- lightning.

Making a chair

The frame of the chair will consist of 2 crosspieces made of wide edged boards, connected to each other by bars. The lumber used for its manufacture will retain saw marks, which will make the whole process much easier. But if you wish and have a thicknessing machine, the frame can be made perfectly smooth.You need to make 2 sidewalls from short and long boards intersecting at right angles. At the same time, at the ends of the boards that will be installed on the floor, corners are cut at 45 degrees.

At the intersection of the crosses, a sample is made on both boards so that when joining they are in the same plane. To do this, a cut is made on each of them to half the thickness, after which the wood is selected with a chisel and trimmed with a plane.

Also, on the edges of short boards, from the side where the legs are cut at 45 degrees, you need to select a quarter 250 mm wide for subsequent fastening of the jumper between the crosspieces.

Before connecting the crosspieces, you need to round off the upper ends of the boards. For short ones, the rounding is done on the inside of the chair, that is, diagonally from the cut corner of 45 degrees, and for long ones, on the same side. First, the required angle is cut, and then it is given a smooth bend with a plane.

After this, the prepared boards are coated with a sample of glue and folded into crosses.

Then, at the intersection, 4 holes are made for installing dowels. All protruding glue must be removed immediately. If you leave it, then the impregnation will not be absorbed into these places.

Next, the crosspieces are connected by a jumper made of boards. It is installed with the ends in the previously selected quarter. The board is secured on each side with glue, one self-tapping screw and a pair of dowels. The screw head is set 1 cm deep. Then its hole from above is clogged with a dowel.

On the back, the crosspieces are connected by three bars, which are also installed on screws and dowels. Two jumpers are placed in the center of the backrest with a small gap, and one on the edge at the headboard. Below at the intersection, the crosspieces are connected by a wide board.After this, the protruding parts of the dowels are cut off, the chair is sanded and impregnated.

Cover with varnish.

The base for the pillow is made from leather, burlap or other durable fabric. 2 pieces of material are cut out and stapled one by one onto the frame of the chair. One of them forms the seat, the second the backrest.

A bag with a zipper is sewn from the upholstery fabric. Its size is selected so that it fits completely on the seat and back. After this, the bag is filled with padding polyester. The resulting pillow is stitched and tightened with twine, to the ends of which furniture buttons are tied. This will make it more presentable and prevent the padding polyester from sticking to one edge.

The pillow is tied to the chair with twine.

You can also sew a small bag for him to store books, newspapers or a phone. It is nailed to the side of the chair.

Watch the video

Similar master classes

Particularly interesting

Comments (0)