How to put a plastic canister to good use in a garage or workshop

Plastic cans from construction primers and car fluids can be used to make drawers for a workshop or garage. They are installed under the top of a workbench or any table, and are used to store screws, bolts and other small items.

For homemade products, a plastic canister of a regular rectangular shape without curly bevels is suitable. It needs to be cut lengthwise along the seam. It can be easily cut with a knife on the sides and bottom, but on the handle and neck the plastic is thicker, so in these places it is better to use a grinder.

As a result, blanks for two drawers are obtained from one canister.

After the cut, the sharp edges of the halves need to be sanded to remove burrs and make them rounded. Next, slats of the appropriate length are screwed onto the long sidewalls of the blanks with self-tapping screws. If the slats are made of hard wood, it is better to drill them first so that they do not split.The protruding length of the screws is cut in place.

To divide the box into 2 halves, a transverse partition of the appropriate size is cut out of plywood and secured with self-tapping screws. It needs to be screwed through the side slats, then the structure will receive additional rigidity, and the slats themselves will definitely not fall off if overloaded. You can make several partitions to get more sections for storing small hardware.

Next, guides are secured under the tabletop. They consist of 2 parallel slats screwed to the back of the tabletop through wooden brackets. The distance between the guides should be 10 mm greater than the width of the box along the canister. The height of the brackets from the tabletop to the top line of the guides should be slightly greater than the width of the side rails on the canister.

The boxes are installed on guides under the workbench.

They are convenient to pull out using the standard handle of the canister. Although the structure is not too rigid, considering that it is loaded only with hardware, this will be enough. Such a box can be easily pulled out onto the table, found the necessary fasteners and put it back in place. If the workbench is large and stands in the center of the room, then you can install many of these boxes on it, you can even arrange them in several levels.

Materials:

- plastic canister 10 liters or more;

- self-tapping screws;

- any wooden slats;

- plywood.

Drawer manufacturing process

For homemade products, a plastic canister of a regular rectangular shape without curly bevels is suitable. It needs to be cut lengthwise along the seam. It can be easily cut with a knife on the sides and bottom, but on the handle and neck the plastic is thicker, so in these places it is better to use a grinder.

As a result, blanks for two drawers are obtained from one canister.

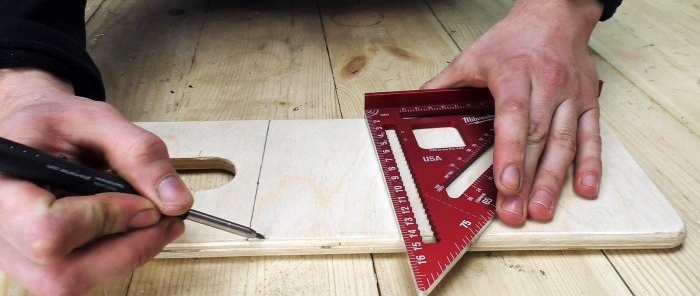

After the cut, the sharp edges of the halves need to be sanded to remove burrs and make them rounded. Next, slats of the appropriate length are screwed onto the long sidewalls of the blanks with self-tapping screws. If the slats are made of hard wood, it is better to drill them first so that they do not split.The protruding length of the screws is cut in place.

To divide the box into 2 halves, a transverse partition of the appropriate size is cut out of plywood and secured with self-tapping screws. It needs to be screwed through the side slats, then the structure will receive additional rigidity, and the slats themselves will definitely not fall off if overloaded. You can make several partitions to get more sections for storing small hardware.

Next, guides are secured under the tabletop. They consist of 2 parallel slats screwed to the back of the tabletop through wooden brackets. The distance between the guides should be 10 mm greater than the width of the box along the canister. The height of the brackets from the tabletop to the top line of the guides should be slightly greater than the width of the side rails on the canister.

The boxes are installed on guides under the workbench.

They are convenient to pull out using the standard handle of the canister. Although the structure is not too rigid, considering that it is loaded only with hardware, this will be enough. Such a box can be easily pulled out onto the table, found the necessary fasteners and put it back in place. If the workbench is large and stands in the center of the room, then you can install many of these boxes on it, you can even arrange them in several levels.

Watch the video

Similar master classes

Particularly interesting

Comments (0)