We bend the profile pipe 90 degrees without welding

It is possible to bend and connect a profile pipe at a right angle without welding. This method will help out if it is not available during the manufacture of various frames and frames.

Tools:

- square;

- felt-tip pen;

- grinder with cutting wheel.

Pipe bending process without welding

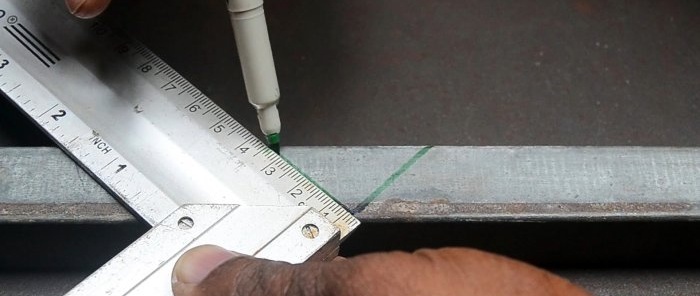

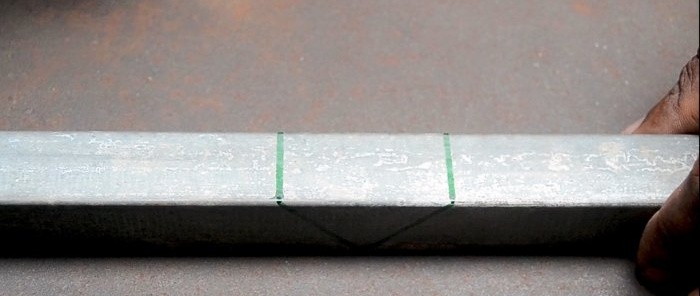

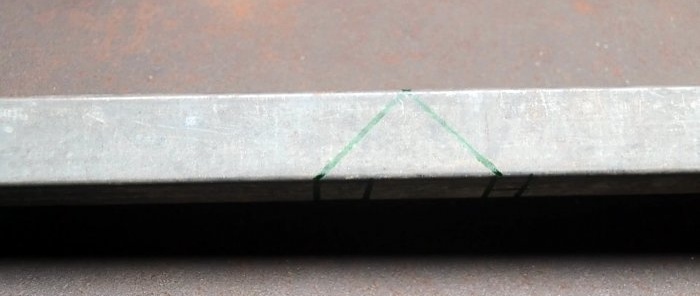

On the sides of the pipe you need to draw a right angle, setting the square at 45°.

They should be located opposite. Along the inside of the pipe bend, the corner points are connected together, resulting in 2 parallel lines.

From the right line you need to step back 10 mm to the right and draw a parallel. A longitudinal line is drawn in the middle between them. From the left line you need to retreat 15 mm to the right, and also draw a parallel. They are connected together by lines along the edges of the pipe.

Using a grinder with a thin cutting wheel, cuts are made along the contours of the side corners. On the inside of the bend you need to cut 2 right parallels and a longitudinal line between them. On the left parallels, the cut is made only on the internal transverse line and longitudinal marks near the ribs.

The cut metal is removed. The protruding tongue is bent outward at a right angle 1 mm from its beginning. The opposite antennae also turn out.

Next, the pipe is bent at a right angle, and its tongue is pressed with tendrils, which return to their original position. The reliable hard corner is ready.

Watch the video

Similar master classes

3 ways to weld a profile pipe at right angles without unnecessary

How to smoothly bend a profile pipe without a pipe bender and heating

Reliable connection of profile pipes without welding or bolts

How to bend a profile pipe at a right angle in the carving style

How to twist a profile pipe for a baluster

How to bend a profile pipe at any angle

Particularly interesting

Comments (3)