Nickel plating at home

Nickel coating protects metal surfaces from corrosion and gives them a characteristic shine. It is abrasion resistant and durable. The nickel plating process can be recreated at home to coat various tools and parts.

You can prepare copper electrolyte yourself. For this, 100 gr. Copper sulfate must be dissolved in 250 ml of water. Then the liquid is filtered from sediment, and 67 ml of battery electrolyte is added to it.

Parts to be plated with nickel must be tied with copper wire and dipped in battery electrolyte.

This will remove rust. Then the remaining acid is neutralized in an aqueous solution of soda.

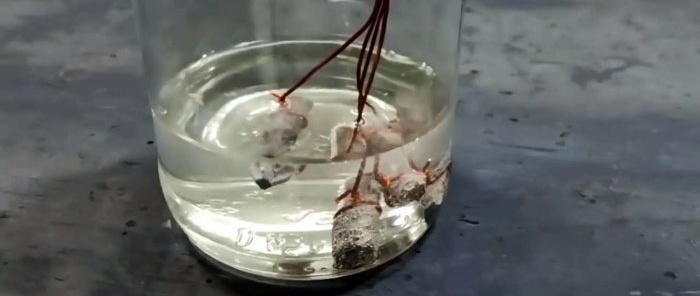

Electrolyte is collected in a separate container and table salt is added. 2 electrodes twisted from nichrome wire are lowered into it and connected to a 5V 1A power supply.

To prevent them from shorting, you need to lay a dielectric between them.

As a result of exposure to electricity, the electrolyte with salt will turn swamp green.During the process, you should not inhale the fumes released, they are harmful. The colored solution must be filtered through a funnel with cotton wool.

The powdered cleaning agent is dissolved in a separate container. Parts for nickel plating need to be washed with a brush to degrease them.

The parts on the wire are immersed in copper electrolyte for 1 minute. They will become coated with copper almost instantly. Then they need to be washed again in a washing solution.

Next, the parts are immersed in the previously made green electrolyte. “+” is supplied to them from the block, and “–” to the second nichrome electrode. Then power is supplied. As a result, the parts will be coated with nickel.

In a similar way, copper and brass products can be coated with nickel, without prior copper plating. The method is very simple and inexpensive to implement.

What you will need:

- electrolyte for batteries;

- nichrome wire;

- copper wire;

- soda;

- powder cleaner;

- copper electrolyte.

You can prepare copper electrolyte yourself. For this, 100 gr. Copper sulfate must be dissolved in 250 ml of water. Then the liquid is filtered from sediment, and 67 ml of battery electrolyte is added to it.

Nickel plating process

Parts to be plated with nickel must be tied with copper wire and dipped in battery electrolyte.

This will remove rust. Then the remaining acid is neutralized in an aqueous solution of soda.

Electrolyte is collected in a separate container and table salt is added. 2 electrodes twisted from nichrome wire are lowered into it and connected to a 5V 1A power supply.

To prevent them from shorting, you need to lay a dielectric between them.

As a result of exposure to electricity, the electrolyte with salt will turn swamp green.During the process, you should not inhale the fumes released, they are harmful. The colored solution must be filtered through a funnel with cotton wool.

The powdered cleaning agent is dissolved in a separate container. Parts for nickel plating need to be washed with a brush to degrease them.

The parts on the wire are immersed in copper electrolyte for 1 minute. They will become coated with copper almost instantly. Then they need to be washed again in a washing solution.

Next, the parts are immersed in the previously made green electrolyte. “+” is supplied to them from the block, and “–” to the second nichrome electrode. Then power is supplied. As a result, the parts will be coated with nickel.

In a similar way, copper and brass products can be coated with nickel, without prior copper plating. The method is very simple and inexpensive to implement.

Watch the video

Similar master classes

Particularly interesting

Comments (0)