How to make a simple vice for a drilling machine without welding

In order to accurately drill parts, not only the absence of runout on the drilling machine and the perpendicularity of the drill are important, but also the reliable fixation of the workpieces. For this purpose, a specially designed vice is used. You can make such a tool with your own hands.

A channel will be used as the base of the vice. Its length is selected individually, depending on the size of the parts that are planned to be clamped in the vise. The side flanges of the channel are cut off, as they are too high.

A wide cutout with strictly parallel sides is made in the center of the channel. A movable sponge will slide over it.

Corners are screwed to the channel shelves. They will allow you to attach the vice to the table. To avoid using nuts, it is better to cut the thread directly in the channel.

Corners are screwed along the edges of the cutout on the front part of the channel. One will serve as a fixed jaw, the second as a stop for the screw. The latter must be strengthened by screwing a thick strip to it.Then the angle and strip are drilled for the screw and threaded.

The sliding sponge is made in the same way as the stop. It should also have a reinforcing strip and a hole for a screw.

The only difference between the sponge is the presence of a hole at the bottom. It is needed to screw the limiter to it.

It consists of 2 strips of metal with a pair of holes for bolts. One of them is an insert with a thickness equal to the cross-section of the channel metal and a width corresponding to the cut at the base. The insert acts as a guide for the sliding jaw. The second strip is a wide limiter that holds the structure from the bottom of the base.

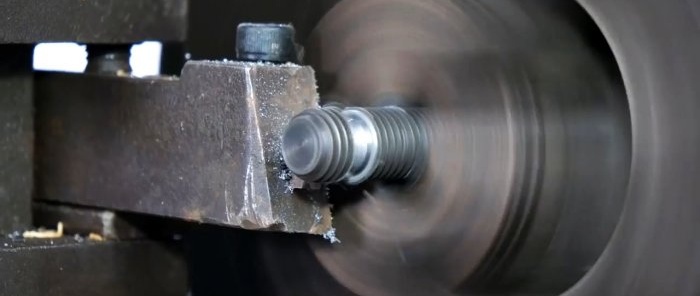

A pin with a thrust thread made of hard steel is used as a vice screw. At one end you need to make a groove for the stopper.

You need to screw a nut onto the second edge and drill it together with the pin to install the handle.

From the strip we grind a stopper for the groove on the hairpin.

You need to make 2 holes in it. The pin is screwed into the vise stop and then caught with a stopper, which is screwed to the sliding jaw.

Then a handle is inserted into the beginning of the screw.

Checking the vice in action.

Materials:

- channel;

- corners;

- threaded rod;

- steel strip with a cross section of 5 mm;

- bolts M10, M6.

Vise manufacturing process

A channel will be used as the base of the vice. Its length is selected individually, depending on the size of the parts that are planned to be clamped in the vise. The side flanges of the channel are cut off, as they are too high.

A wide cutout with strictly parallel sides is made in the center of the channel. A movable sponge will slide over it.

Corners are screwed to the channel shelves. They will allow you to attach the vice to the table. To avoid using nuts, it is better to cut the thread directly in the channel.

Corners are screwed along the edges of the cutout on the front part of the channel. One will serve as a fixed jaw, the second as a stop for the screw. The latter must be strengthened by screwing a thick strip to it.Then the angle and strip are drilled for the screw and threaded.

The sliding sponge is made in the same way as the stop. It should also have a reinforcing strip and a hole for a screw.

The only difference between the sponge is the presence of a hole at the bottom. It is needed to screw the limiter to it.

It consists of 2 strips of metal with a pair of holes for bolts. One of them is an insert with a thickness equal to the cross-section of the channel metal and a width corresponding to the cut at the base. The insert acts as a guide for the sliding jaw. The second strip is a wide limiter that holds the structure from the bottom of the base.

A pin with a thrust thread made of hard steel is used as a vice screw. At one end you need to make a groove for the stopper.

You need to screw a nut onto the second edge and drill it together with the pin to install the handle.

From the strip we grind a stopper for the groove on the hairpin.

You need to make 2 holes in it. The pin is screwed into the vise stop and then caught with a stopper, which is screwed to the sliding jaw.

Then a handle is inserted into the beginning of the screw.

Checking the vice in action.

Watch the video

Similar master classes

Particularly interesting

Comments (0)