How to greatly increase the stroke length of a bottle jack

Purchasing a new hydraulic cylinder for self-propelled equipment or a stationary mechanism to replace a failed one is associated with considerable costs. Often such a breakdown occurs at the most inopportune moment and replacement is urgently needed. You can quickly make a similar analogue from an ordinary hydraulic bottle jack if you have some skills in working with metal.

Will need

Materials:- Hydraulic bottle jack;

- steel round pipes of two diameters;

- steel rod;

- new sealing unit;

- steel power washer;

- aerosol primer and paint;

- fastening unit and screws.

The process of increasing the stroke length of a conventional bottle jack

We fix the base of the hydraulic bottle jack in a vice, lower the screw all the way down and use a spanner to unscrew the nut that presses the jack body to the base.

We pour out the working fluid from the housing, which also serves as an oil reservoir.Remove the housing, piston with seals and cylinder.

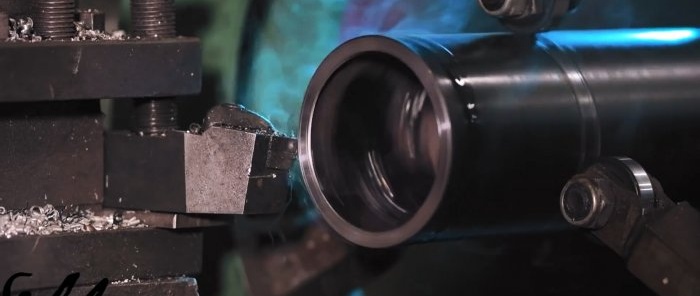

We measure the thread profile on the removed cylinder, clamp a long pipe of the same diameter as the old cylinder into the lathe chuck, grind it at both ends to the desired size and shape, and cut the measured thread profile.

On a lathe we grind a steel rod of the estimated length and diameter on one side for the seal, and on the other for the support heel. We round the thread profile with a file, sandpaper and remove metal particles with a brush.

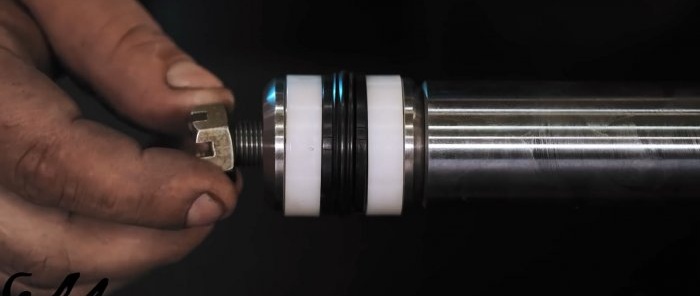

We put a new sealing unit on one end of the piston rod, secure it with a castle nut and lock it.

We insert the extended piston rod into the long cylinder, put on the nut with a seal and tighten it.

We process the outer side of the old pipe with a grinder, shape it to the required size using a band saw, insert it into the chuck of a lathe with a steady rest, trim it and grind one end into a cone.

On a lathe, we adjust a strong thickened ring along the internal and external diameters to the size of the processed end of a large pipe, and weld it to the end using gas-acetylene welding.

We reprocess the welded ring and the adjacent part of the pipe, removing metal deposits after welding and restoring the original taper. We just trim the other end of the pipe.

We install the end of the pipe with the welded ring on the base and tighten the nut with a seal on top.

We fill it with working fluid using a funnel, pull out the rubber plug from the old jack body and close the oil filler hole in the upper part of the new oil reservoir with it.

We check the performance of the modernized jack with a stroke length increased several times compared to a standard jack, apply primer to its surface, let it dry and paint it.

We screw the support foot onto the thread of the cylinder-rod, screw the suspension unit to the base, and our jack can successfully replace an unusable hydraulic cylinder on self-propelled equipment or a stationary mechanism.

Watch the video

Similar master classes