How to make a connection of profile pipes without welding at right angles with a jib

If you don't have a welding inverter, you can still work with profile pipes and join them in an alternative way. For this purpose, various fastening methods have long been invented, which are no less reliable than welding. Let's consider one of them.

What you will need:

- profile pipe;

- M6 bolts with nuts – 2 pcs.;

- blind rivets – 4 pcs.

The process of connecting pipes without welding

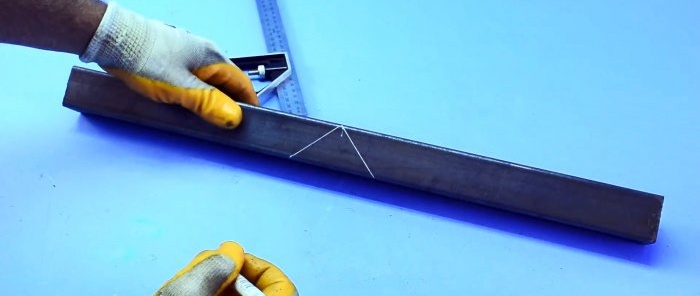

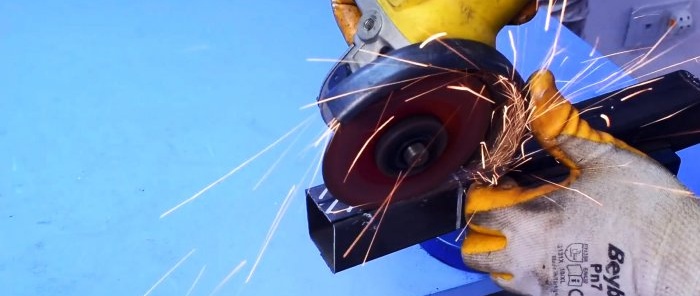

From the first profile pipe you need to form a right angle by bending. To do this, you need to make markings on it from the bend point in 2 directions at 45 degrees. The same markings are made on the opposite wall. The wedge drawn in this way is cut out with a grinder.

Now the pipe can be bent at a right angle. If it is thick-walled and nothing works, then you can lightly cut the remaining intact wall.

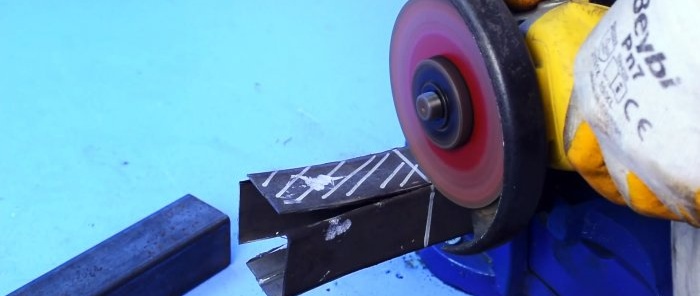

Next we move on to the second pipe. It should be cut from the edge along all corners. Any 2 opposite walls are bent to the side.

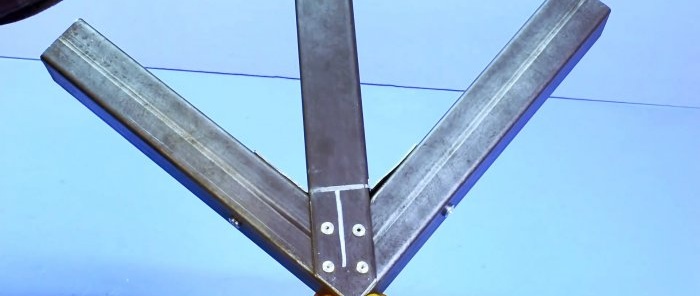

It is then placed over the inner corner formed by the first pipe.

Now all that remains is to drill the blanks and tighten them with bolts.

After this, the connection is strengthened with blind rivets.

The walls of the second pipe protruding beyond the corner are cut off.

Watch the video

Similar master classes