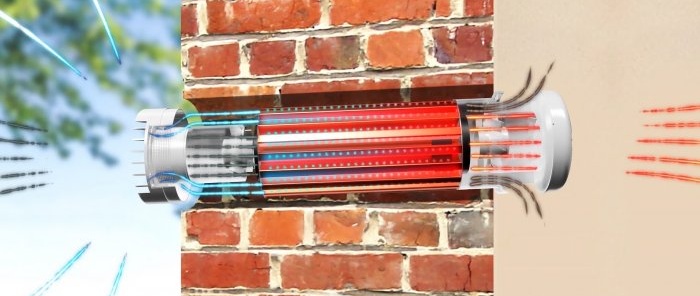

How to make simple ventilation with recovery in a house or garage to reduce heating costs

For a comfortable stay in a room, high-quality ventilation is required. However, along with the outflow of old air and the supply of fresh air, large heat losses occur. To solve this problem, expensive purchased recuperators are used. They take heat from the outgoing air and give it to the incoming air. You can make such a system with your own hands from inexpensive components.

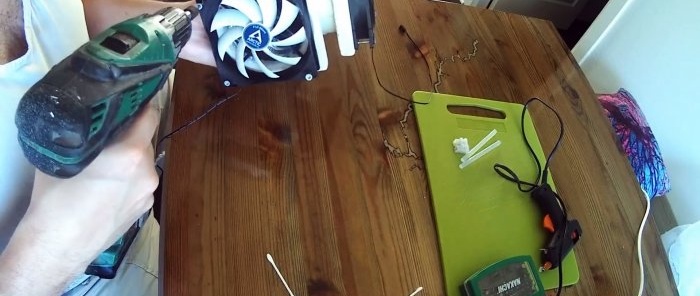

Materials:

- Plastic pipe 110 mm;

- plastic tee 110 mm;

- corrugated pipe 50 mm;

- 120 mm fans – 2 pcs.;

- silicone sealant.

Ventilation system manufacturing process

First of all, measure the thickness of the wall. Then you need to make 2 flanges from plywood to mount the fans.

Now we insert 3 corrugations into the tee.

The gaps between them at the end must be sealed. To do this, sealant is poured. Before this, you can stuff scraps of foamed polyethylene into them so that the silicone does not sink deeper.

Next, we take a pipe and drill ventilation holes in it in a circle through which air will be sucked in. The perforation is made so that the distance between it and the tee exceeds the thickness of the wall.

The perforated pipe is connected to the tee. The corrugation is accordingly wound inward. Then we seal the open end of the pipe with silicone.

When the sealant has dried, you can trim off the overhanging ends of the corrugation. After this, glue a mosquito net to the end of the pipe.

The previously made flanges need to be glued with hot glue to the outlets of the tee. Then fans are screwed onto them. Opposite the pipe, the fan is turned so that it blows air into the corrugations. The side one is installed in reverse to suck in the flow through the perforation.

Now we drill a hole in the façade wall and take the system outside. Fans must remain indoors. When ventilation is turned on, the exhaust air will heat the tubes, and they, in turn, will be able to transfer heat to the supply air. This will significantly reduce the cooling of the room.