Simple nickel plating of parts at home with your own hands

You can restore a nickel-plated surface or plate a new part with nickel at home. Moreover, this does not require expensive materials and deep theoretical knowledge. You just need to be careful with chemically active substances and use protective equipment.

Will need

Materials:- electrodes based on nickel alloys;

- plastic water bottle;

- glass jar;

- table vinegar;

- table salt;

- power supply 4.75 V and 0.55 A;

- flat wooden board;

- wires with clamps;

- thin soft wire;

- metal part for restoration.

The process of nickel plating metal parts at home

It is known that if electrodes are placed in an electrolyte and voltage is applied to them, then the transfer of substance from the positive electrode to the negative one begins. Based on this phenomenon, we will restore the nickel coating on a metal part, which has degraded over time.

We use nickel-containing electrodes as a source of nickel. To remove the coating, place the electrode in a plastic bottle with water for about 2 hours.

Then we squeeze the coating with pliers, and it crumbles easily.

To completely remove the coating, wipe it with paper napkins, treat it with sandpaper and wipe it with the same napkins. We cut the cleaned electrode into two halves, which will serve as electrodes.

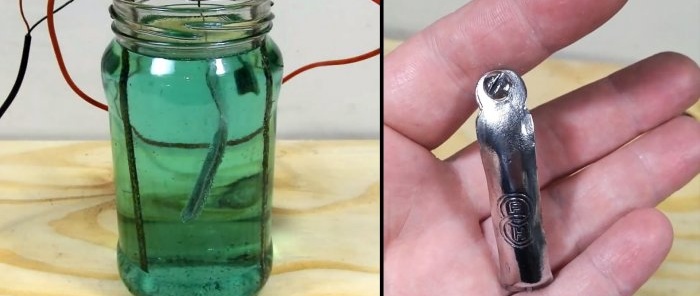

In a glass jar, prepare an aqueous solution of the electrolyte with the addition of table vinegar and table salt in certain proportions, and mix everything thoroughly with a spoon until the salt is completely dissolved.

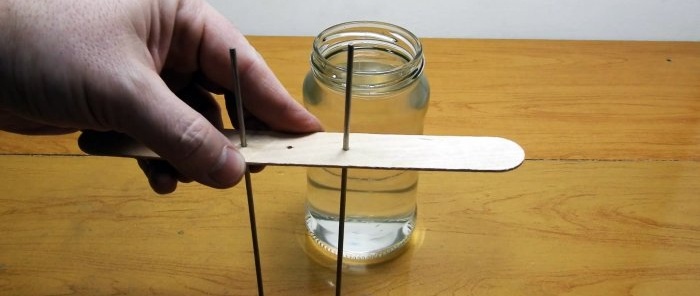

In a wooden plank (this could be an ice cream stick) we make three holes in the center. We place electrodes in the outer holes and lower them into the electrolyte, and connect the voltage.

The greatest activity is observed on the negative electrode in the form of intense bubble production. After about 1 hour, everything calms down and during this time the electrolyte is saturated with dissolved nickel ions.

After 2 hours, the positive electrode begins to turn green and you can clearly see how nickel leaves the positive electrode and is deposited on the negative electrode.

We begin preparing the metal part for nickel plating. We remove rust, dirt and deposits from the surface with a Dremel. Degrease with a cloth soaked in alcohol, white spirit or a special liquid.

We fasten the parts for nickel plating with soft wire to a wooden board between the electrodes. Attention! Now polarity is very important! We connect the electrodes to the positive terminal, and the workpieces to the negative terminal.

Apply voltage through the power supply for three minutes and check the quality of the nickel plating.If we are not satisfied with it, then we repeat the cleaning of the parts, especially degreasing, with greater care. After this, a second three-minute electro-galvanic procedure gives excellent results.

We tightly close the lid of the electrolyte in a glass jar and pack the dry electrodes in paper napkins. They will be useful for new nickel plating jobs.

The surfaces of parts subjected to nickel plating are processed with a grinding wheel and installed in their original place.

Watch the video

A way to coat steel with zinc at home without electrolysis - https://home.washerhouse.com/en/7413-sposob-bez-jelektroliza-pokryt-stal-cinkom-v-domashnih-uslovijah.html