How to Make a Compact Hand Grinder Using a 775 DC Motor

When creating homemade products in a home workshop, a lot of time and effort is spent on processing the workpieces after sawing, drilling, milling, etc. using a hand file and sandpaper. By making a compact hand grinder, these works can be made easier and faster several times.

Will need

Materials:- endless sanding belt;

- clamp handle;

- rolling bearings;

- bolts, washers and nuts;

- DC motor 775 DC 12-24 V -

- aluminum corners are different;

- cylindrical pulleys, etc.

The process of making a miniature hand grinder

We cut a piece from the aluminum corner with a length determined by the endless sanding belt and the diameters of the cylindrical pulleys.

We mark a mark on the corner shelf and draw a longitudinal line taking into account the distance from the center of the electric motor shaft to the external size of the housing.To the end of the same shelf we attach the corner bracket included in the engine kit, taking into account the previously drawn line, and outline the central and two holes on the sides for fastening. We reduce the height of the shelf and drill holes according to the markings. We remove burrs and blunt the edges.

From the outside, in the corner shelf with a reduced height, we insert the central protrusion of the motor with a high torque into the hole and secure it with two screws.

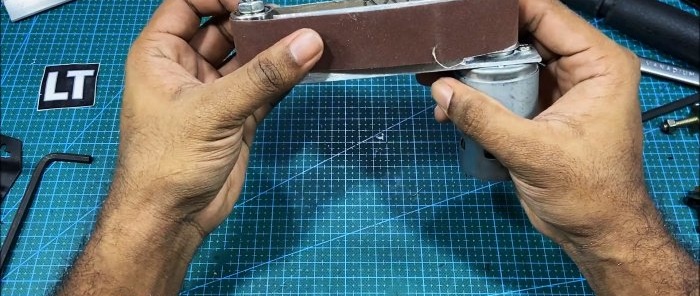

We put a cylindrical pulley on the axis of the electric motor shaft and secure it with a locking screw.

We put an endless sanding belt on the pulley and mark a place to install the second pulley on the corner in the form of an elongated slot with an exit to the end of the corner.

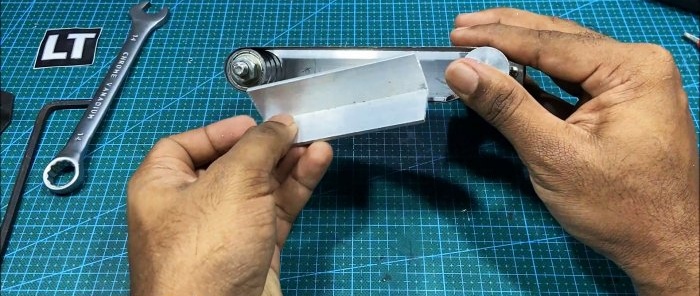

We cut off a fragment from the entire corner flange on each side, taking into account the transverse dimensions of the drive and driven pulleys. We remove burrs, round the edges and corners with a hand file.

We assemble the driven pulley by installing a bolt in the elongated slot on the outside, onto which we string washers and rolling bearings alternately from the inside of the shelf. Tighten the assembly with a nut using wrenches.

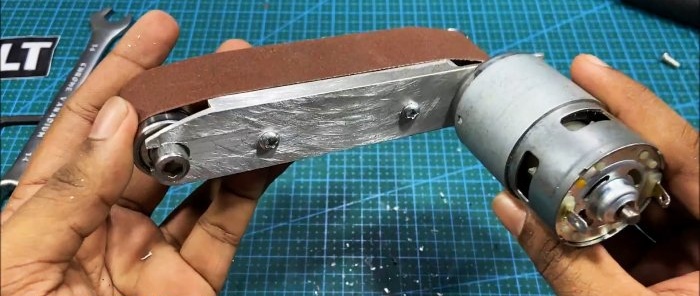

We install the electric motor, pulley, and endless sanding belt in place and connect the motor to the power supply or battery using wires.

We attach a section of the corner to the vertical shelf of the base angle from the inside using screws and nuts so that its horizontal shelf serves as a support for the endless sanding belt during operation.

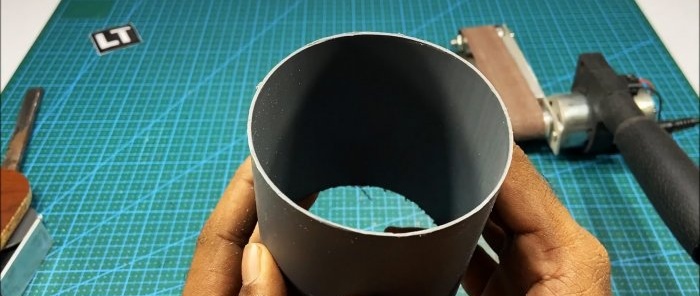

We remove the casing from the electric motor housing and put the handle clamp in its place and tighten it by turning the handle to the right. Moreover, the handle can be fixed in any position.

We glue terminal contacts and a switch to the handle. Using wires and a soldering iron, we connect them to each other and the electric motor.

We connect the grinder to the power supply, set the switch to the working position and check the tool in operation.

It can be used to process parts of any shape made of metal, plastic, wood, etc.

Watch the video

Similar master classes