How to make a super grinder yourself from an ordinary grinder

Purchasing a factory-made belt grinder is associated with high costs. Also, the industrial grinder has large dimensions and may require a significant area for its installation.

But it is possible to make this grinding machine yourself in a home workshop without high costs and, at the same time, compact size, based on a standard grinder.

It should be noted that the work will require us to take some time, certain skills, and prepare materials, equipment and tools.

To make homemade products, we will need quite accessible and inexpensive materials:

Some operations can be done manually, but the work will go faster and easier if you have:

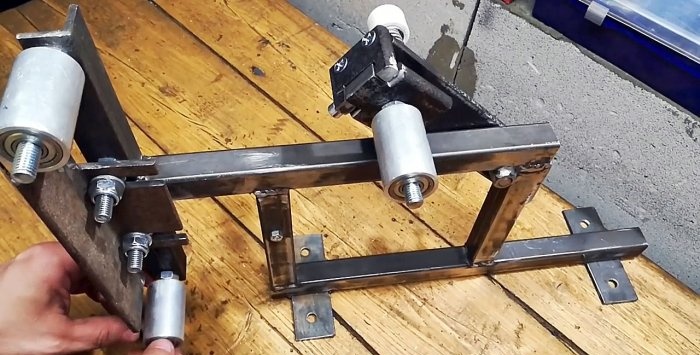

Our homemade product will consist of three main components:

It is better to prepare in advance, if not drawings, then at least calculations of the main dimensions. Using measuring devices, we will transfer them to the workpieces and only after that we will begin cutting.

We will weld the machine frame from a square pipe.

We will make one of the elements from a steel equal-flange angle, which, after marking, cutting and drilling, will be a unit with identical cutouts along the edges of one shelf, and in the remaining part two equal holes are made closer to the adjacent shelf and its edges. Later this unit will be further developed.

Taking the above-described knot as a template, we mark a steel equal-flange angle of smaller dimensions, attaching it to the shortened shelf and aligning their centers. We transfer the centers of the two holes to one of the shelves of the smaller corner. Along the edges we mark two more holes, equidistant from the ends. Then we drill 4 holes according to the markings, removing burrs from all holes.

We complete the assembly made from a large corner: we cut grooves with a cutting disc from the edge of the shelf to the holes, the width of which is equal to the diameter, remove the burrs and round the edges with a file.

Using a welding template, we weld a small corner with four holes with another shelf symmetrically to the end of a section of profile pipe - a frame element.

We assemble the base units in the required order and weld them together.

We mark the metal strip, measuring it with the length of one part of the element (12 cm), made from a small corner. In the inner upper corner of the frame we place an extended nut, which will then be welded.

We place a strip under the frame so that it is parallel to the small corner and protrudes 12 cm beyond the longitudinal element of the frame. Mark the drilling location on the strip along the nut, make a hole and cut a thread in it with a tap. We weld the nut in place.

We screw the strip with the hole to the nut with a bolt and install it at an angle of 45 degrees to the adjacent frame elements.

In this position on the strip, draw a line using the outer edge of the vertical frame element and cut it along the markings. We weld a limiter for the lever with an oblique cut to the frame element in place. We process the lever in a circular manner on a grindstone.

From the rest of the strip, we cut off a fragment with a height slightly less than its width and make a symmetrical notch in it from the smaller end. Using this part as a template, we cut off a slightly longer fragment from the strip, but with a corresponding spike.

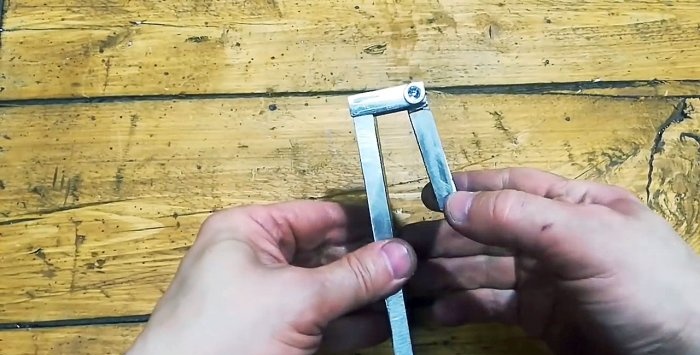

We connect these two elements so that they can freely rotate relative to each other thanks to one axis passing through a through hole in two protrusions and one spike.

We drill two holes in the flat end of the lever and cut threads into them. We secure the moving unit with two screws to the end of the lever, and the entire system with a bolt to a nut welded to the frame.

Closer to the sharp end of the lever and in the vertical frame element opposite, we drill holes and secure bolts and nuts in it. We connect a spring to them to hold the lever in its extreme position.

We drill holes in the lever and the moving element, and then cut threads into them.

We cut two identical fragments from a thin metal strip. We make holes in them along the edges and weld them to the frame for stability or fastening to another base.

We secure the bolts with nuts in the outer holes in the element from the corner. We secure the pin in the hole of the movable “tongue” on the lever with a nut.

We insert and secure shorter bolts into the two central holes. We put washers on top of the nuts, from the outside, using the slots, we install an element made from a large angle and tighten it with nuts.

We put a spring and a washer on the shaft of the bolt with a plastic head and screw it, compressing the spring, into the threaded hole in the movable lever so that the end of the bolt rests against the “tongue” and it can be deflected if necessary.

From aluminum cable sleeves we make three identical tubes and one slightly longer. We press one bearing into the short tubes into the prepared sockets, and into the long tubes we press an extended hex nut using a screw press.

We install washers on the rods of the three bolts, and then tubes with bearings pressed into them, securing them with nuts.

Using a metal ruler, we align the outer side of the flange of the element from the large corner into the plane with the tubes at the ends of the element from the smaller corner, and tighten it in this position with nuts.

From a metal strip of the required width, we cut out four fragments of the same length and two more - one shorter, the other longer. From them we form a unit for attaching an angle grinder with the ability to change its position in two planes.

The attachment point for the angle grinder, in turn, will be attached to the base of the frame using two bolts welded to it in advance.

We install the grinder in place, and screw an aluminum tube with a nut pressed into it onto the spindle.

We put the spring of the movable lever in place and put a ring tape made from a strip of sandpaper on the aluminum rollers.To do this, overcoming the spring force, we shift the tension roller towards the driven one, and after installing the tape on the rollers, release it to create a tension force.

We turn on the grinder and watch the tape. If it moves to the side, then by rotating the screw head, we change the position of the axis of the adjusting roller and counteract the displacement of the tape.

All that remains is to install the work table on the side of the working branch of the sanding tape using an adjustable console mounted on the frame.

To give the device an aesthetic appearance, it can be disassembled and the parts can be painted with anti-rust enamel, and then reassembled.

But it is possible to make this grinding machine yourself in a home workshop without high costs and, at the same time, compact size, based on a standard grinder.

It should be noted that the work will require us to take some time, certain skills, and prepare materials, equipment and tools.

Will need

To make homemade products, we will need quite accessible and inexpensive materials:

- different metal (angle, profile pipe, strip);

- threaded parts (nuts, washers, screws, bolts, studs);

- tension and compression springs;

- bolt with plastic handle head;

- aluminum cable sleeves;

- bearings;

- enamel against rust.

Some operations can be done manually, but the work will go faster and easier if you have:

- grinder with cutting disc;

- drilling machine;

- welding equipment;

- drill with drill and countersink;

- square and pencil;

- caliper and tape measure;

- core and hammer;

- metal file;

- tap, screwdriver and keys.

Manufacturing technology of a grinder from an angle grinder

Our homemade product will consist of three main components:

- power frame (frame);

- drive (grinder);

- tension roller system;

It is better to prepare in advance, if not drawings, then at least calculations of the main dimensions. Using measuring devices, we will transfer them to the workpieces and only after that we will begin cutting.

We will weld the machine frame from a square pipe.

We will make one of the elements from a steel equal-flange angle, which, after marking, cutting and drilling, will be a unit with identical cutouts along the edges of one shelf, and in the remaining part two equal holes are made closer to the adjacent shelf and its edges. Later this unit will be further developed.

Taking the above-described knot as a template, we mark a steel equal-flange angle of smaller dimensions, attaching it to the shortened shelf and aligning their centers. We transfer the centers of the two holes to one of the shelves of the smaller corner. Along the edges we mark two more holes, equidistant from the ends. Then we drill 4 holes according to the markings, removing burrs from all holes.

We complete the assembly made from a large corner: we cut grooves with a cutting disc from the edge of the shelf to the holes, the width of which is equal to the diameter, remove the burrs and round the edges with a file.

Using a welding template, we weld a small corner with four holes with another shelf symmetrically to the end of a section of profile pipe - a frame element.

We assemble the base units in the required order and weld them together.

We mark the metal strip, measuring it with the length of one part of the element (12 cm), made from a small corner. In the inner upper corner of the frame we place an extended nut, which will then be welded.

We place a strip under the frame so that it is parallel to the small corner and protrudes 12 cm beyond the longitudinal element of the frame. Mark the drilling location on the strip along the nut, make a hole and cut a thread in it with a tap. We weld the nut in place.

We screw the strip with the hole to the nut with a bolt and install it at an angle of 45 degrees to the adjacent frame elements.

In this position on the strip, draw a line using the outer edge of the vertical frame element and cut it along the markings. We weld a limiter for the lever with an oblique cut to the frame element in place. We process the lever in a circular manner on a grindstone.

From the rest of the strip, we cut off a fragment with a height slightly less than its width and make a symmetrical notch in it from the smaller end. Using this part as a template, we cut off a slightly longer fragment from the strip, but with a corresponding spike.

We connect these two elements so that they can freely rotate relative to each other thanks to one axis passing through a through hole in two protrusions and one spike.

We drill two holes in the flat end of the lever and cut threads into them. We secure the moving unit with two screws to the end of the lever, and the entire system with a bolt to a nut welded to the frame.

Closer to the sharp end of the lever and in the vertical frame element opposite, we drill holes and secure bolts and nuts in it. We connect a spring to them to hold the lever in its extreme position.

We drill holes in the lever and the moving element, and then cut threads into them.

We cut two identical fragments from a thin metal strip. We make holes in them along the edges and weld them to the frame for stability or fastening to another base.

We secure the bolts with nuts in the outer holes in the element from the corner. We secure the pin in the hole of the movable “tongue” on the lever with a nut.

We insert and secure shorter bolts into the two central holes. We put washers on top of the nuts, from the outside, using the slots, we install an element made from a large angle and tighten it with nuts.

We put a spring and a washer on the shaft of the bolt with a plastic head and screw it, compressing the spring, into the threaded hole in the movable lever so that the end of the bolt rests against the “tongue” and it can be deflected if necessary.

From aluminum cable sleeves we make three identical tubes and one slightly longer. We press one bearing into the short tubes into the prepared sockets, and into the long tubes we press an extended hex nut using a screw press.

We install washers on the rods of the three bolts, and then tubes with bearings pressed into them, securing them with nuts.

Using a metal ruler, we align the outer side of the flange of the element from the large corner into the plane with the tubes at the ends of the element from the smaller corner, and tighten it in this position with nuts.

From a metal strip of the required width, we cut out four fragments of the same length and two more - one shorter, the other longer. From them we form a unit for attaching an angle grinder with the ability to change its position in two planes.

The attachment point for the angle grinder, in turn, will be attached to the base of the frame using two bolts welded to it in advance.

We install the grinder in place, and screw an aluminum tube with a nut pressed into it onto the spindle.

We put the spring of the movable lever in place and put a ring tape made from a strip of sandpaper on the aluminum rollers.To do this, overcoming the spring force, we shift the tension roller towards the driven one, and after installing the tape on the rollers, release it to create a tension force.

We turn on the grinder and watch the tape. If it moves to the side, then by rotating the screw head, we change the position of the axis of the adjusting roller and counteract the displacement of the tape.

All that remains is to install the work table on the side of the working branch of the sanding tape using an adjustable console mounted on the frame.

To give the device an aesthetic appearance, it can be disassembled and the parts can be painted with anti-rust enamel, and then reassembled.

Watch the video

Similar master classes

How to make a belt grinder without welding on the base

Simple 12V mini grinder

The simplest grinder without welding and turning from a washing machine engine

A stand for an angle grinder made from the handle of a children's bicycle. Extremely

Making a long cutting stand for an angle grinder

A very simple grinding machine made from available materials

Particularly interesting

Comments (0)