Miniature and functional do-it-yourself grinding attachment for an angle grinder

A belt grinder is the most convenient universal option for grinding and sharpening. It can be used to process flat parts, make bevels on knives, and sharpen almost any tool. In the factory version, such equipment is cumbersome, and besides, it costs far from a penny. We offer a version of a homemade compact grinder driven by an angle grinder.

Materials:

- Sheet steel 3-4 mm;

- steel pipe 32 mm;

- polypropylene pipe 32.25 mm;

- gas shock absorber;

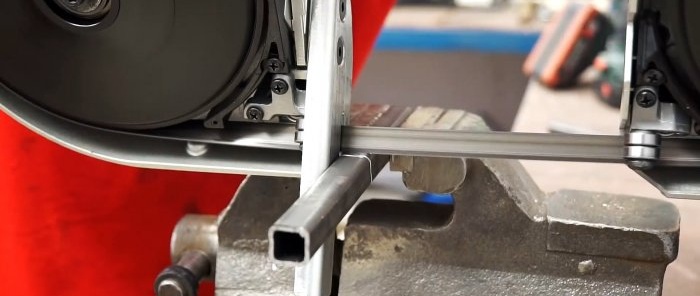

- profile pipe 10x10 mm;

- square 8 mm;

- bearings with an outer diameter of 26 mm – 2 pcs.;

- extended nut M14;

- M10 stud.

Welding electrodes for general purposes on AliExpress at a discount - http://alii.pub/606j2h

The console manufacturing process

It is necessary to cut a plate from sheet steel, approximately 150x250 mm. The corner of the part is cut off to weld the clamp.

The fastening clamp is given from a section of pipe. A ring of it needs to be cut lengthwise and welded onto the edges of the nut attached to the bolt.

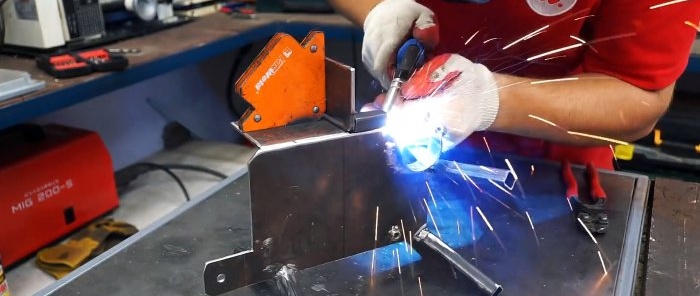

The clamp is welded onto the plate.

The corner of the plate opposite the clamp needs to be cut out, removing a rectangular part 50 mm wide. Then you need to prepare a strip, 50x150 mm.

A rotating mechanism such as a door hinge is welded from the strip and trimmings. A hole for an M10 bolt is drilled in its short flap and a thread is cut into it. On the contrary, a large hole is drilled in the second half.

The loop must be screwed to the plate with the clamp. Next, you need to install a gas shock absorber on the workpiece. To attach it, holes are drilled in the hinge and the main plate.

A side stop made of sheet steel is welded onto the longitudinal side of the frame from the clamp side.

Then 3 legs are bent from the profile pipe and welded as in the photo.

Now we need to make a support table to place the parts during grinding. To do this, a small piece of profile tube is welded onto the side plate. The table itself is made of sheet steel. To attach it to the tube, you need to weld a pin from an 8 mm square rod to it.

The drive roller of the machine is made of steel pipe. To secure it, you will need to place a washer on the angle grinder spindle and screw on an extended M14 nut. The washer and nut are welded. The fastener is then welded into the tube.

The driven roller can be made from 32 mm polypropylene pipe. A short spacer made of 25 mm pipe is placed in it. Bearings are pressed into the sides. Then the roller is tightened with an M10 stud and nuts.

Finished parts can be painted.

Then we clamp the angle grinder on the frame with a clamp, install a loop and a shock absorber.

The drive roller is screwed onto the angle grinder spindle, and the driven roller is installed in the loop.

Thus, the latter will be supported by a shock absorber. After this, you can install the tape and use the machine for its intended purpose.

By tightening or unscrewing the shock absorber mounting bolt on the hinge, you can change the angle of the driven roller, thereby adjusting the position of the belt. The machine operates in vertical and horizontal positions.

Watch the video

Similar master classes