An unusual way to solder aluminum

Aluminum is a rather difficult metal to solder, since the oxide film prevents solder from sticking to it. You can get rid of it in different ways, often time-consuming. Few people know that aluminum can be tinned by copper plating. After this it will be quite easy to solder.

Materials:

- Copper sulfate;

- water;

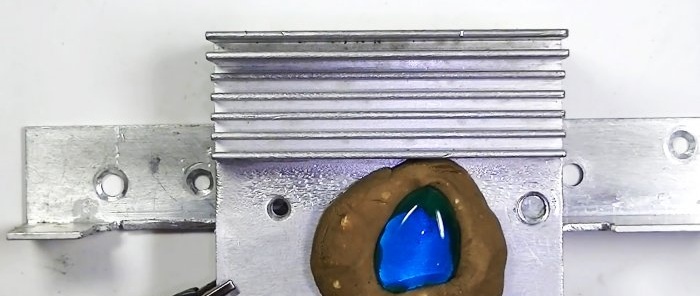

- plasticine;

- DC source.

Aluminum soldering process

It is necessary to prepare a concentrated aqueous solution of copper sulfate.

On the surface of the aluminum that needs to be tinned, sides are made of plasticine. Then the solution is poured into this mold.

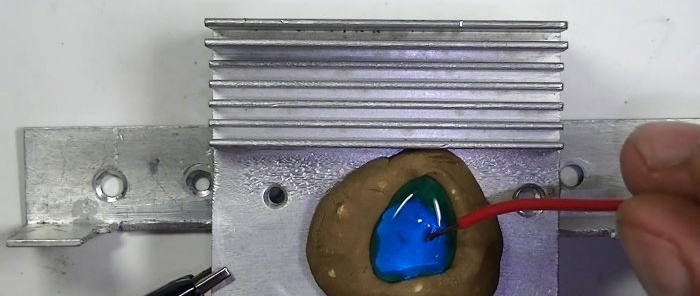

Next, we take the negative wire of the transformer and connect it to the aluminum billet, and dip the positive wire in a bath of vitriol, but so that it does not touch the metal.

We wait a minute, or even less if the transformer is powerful. After this, drain the solution and remove the plasticine.

A copper coating will remain on the surface under the bath, to which the solder adheres remarkably well. Please note that the soldering iron must heat the surface well.

If the transformer power is sufficient, the entire preparation process takes a couple of minutes, so the method is worth adopting.