How to make a winch from available materials

In a home workshop, a small cable winch with a gear drive for lifting and lowering loads would be quite useful. It will save a lot of effort and time. It can be made from the simplest and most affordable materials and parts. Moreover, any adult who has some experience working with metal can cope with such work.

Will need

Materials:

- 3 cylindrical gears with one-sided hub;

- pinion shaft;

- sheet metal remains;

- steel round rod;

- round rod with external thread;

- several standard nuts;

- round pipes of different diameters.

Tools: grinder, drilling machine, welding machine, wrenches, hand screwdriver, ruler, marker.

The process of manufacturing a gear-driven manual cable winch from available materials

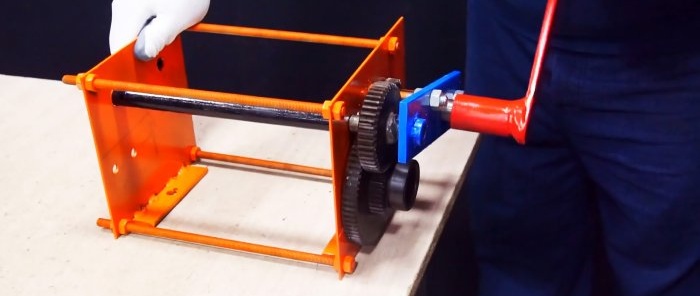

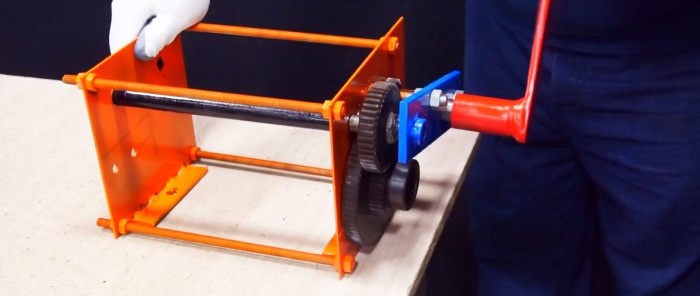

We place the smallest one on the largest gear so that the hub of the first gear is inside the second, the hub of which, in turn, should be directed outward. In this position we weld them to each other.

We place the gears and pinion shaft in the meshed position as they will be located in the winch to ensure operation and reduce the load on the drive. After this, we cut out 2 identical plates of the required sizes from sheet metal.

We drill a hole in one of the plates for the double gear shaft, insert it through the hole from the outside and weld it to it. We also drill holes in the plate at the ends of the single gear shaft and the pinion shaft, but direct their shafts in the opposite direction.

We cut off the required length from the metal strip, drill holes in it for the shaft of the single gear and the pinion shaft, as well as 2 more holes for fastening. We put it on these shafts, and insert rods with external threads into the mounting holes and weld them to the plate. Then, using the nuts on the rods, we fix the strip parallel to the plate.

We drill 4 holes in the corners of the base plate, insert 4 long rods with external threads into them from the side opposite the gears, and fasten the second plate with nuts on their free ends.

We cut off a slightly shorter fragment from the round pipe, the part of the gear shaft protruding beyond the strip. We make the manual drive from a narrow strip with a bolt welded at one end with a piece of freely rotating pipe put on it, and at the other we drill a threaded hole, to which we weld a previously prepared fragment of a round pipe on the opposite side of the handle.

In the pipe fragment, we drill 2 holes in the longitudinal direction on the side surface, cut threads into them and screw in 2 fixing bolts using a flat-head screwdriver. We put the pipe fragment on the end of the gear shaft and tighten the bolts.

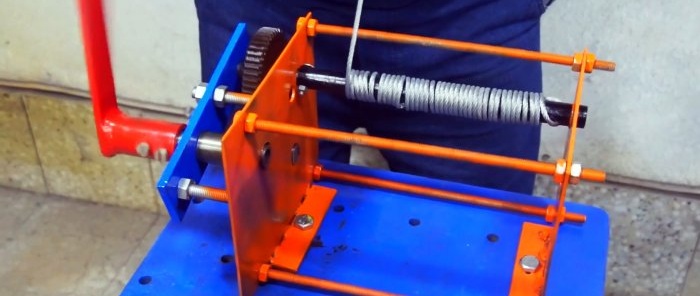

We put a round pipe on the end of the single gear shaft, passing it through the hole in the far plate. We drill through holes in the pipe closer to the plates. Insert a bolt into the hole located closer to the plate with the fixed gears and tighten the nut on the opposite side.

We weld one strip with a hole in the center to the base of the plates from the inside in a horizontal position.

We paint the resulting cable winch in accordance with ergonomic principles and technical design requirements. We insert the end of the cable into the hole in the pipe near the far plate, pass the other end through the block on the ceiling, and secure it to the load being lifted.

When the manual drive rotates, the cable is wound around the pipe and lifts the load. When the handle is rotated in the opposite direction, the cable is released and the load is lowered.

Watch the video

Similar master classes