A penny device for easy cutting of PVC pipes

Making a device for cutting PVC pipes

On the bell we mark 4 petals equidistant from each other along the circumference, each 2 cm wide, and at the beginning of the bend, we drill 8 holes with a diameter of 6 mm according to the markings. From each hole in the opposite direction from the bell, we draw parallel straight lines and, using a metal ruler, draw arcs on the surface of the bell between those holes, the material between which is to be removed.

Using a grinder, we remove the ring from the end of the bell to the front wall of the groove designed to accommodate the sealing ring, which we also remove because it is no longer needed in the future.

We heat the bases of the petals with hot air from a hair dryer and bend them inward 180 degrees one by one. We shorten the ends of the petals so that they do not protrude beyond the end of the bell, which we sand with sandpaper.

We remove the rod from the plastic handle of the old screwdriver and instead hammer in a plastic dowel of the appropriate diameter and length. Insert a screw or self-tapping screw into the mounting hole of the base of the reinforced plastic clamp from the inside and screw it tightly into the dowel inside the handle.

In one of the whiskers of the plastic clamp, we drill a hole with a diameter of 6 mm, into which we install an unhardened bit made of chrome-vanadium steel and experimentally, using various files, we form a cutter that will not only cut through the pipe wall, but also form a chamfer profile.

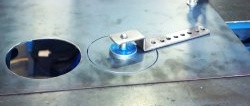

We press the cutter into the hole of the clamp, not with hammer blows, so as not to break the plastic, but by squeezing it with the jaws of a vice. Our pipe cutting device is almost ready for use.

The device is quite simple to operate. Place a mark on the pipe along which the cut needs to be made. We put a restrictive clamp on the pipe and move it until the mark of the cutter leaning against it coincides with the mark on the pipe.

The cutting process involves rotating the cutter around the pipe. The cutting speed and chamfer size directly depend on the profile and sharpening of the cutter, as well as on the clamping force. Here the clamp is the pipe holder. Its elasticity should be sufficient to insert the cutter into the material and nothing more.

The cutter completely cuts off pipes with a diameter of 32 or 50 mm, since they are quite rigid, but pipes with a diameter of 110 mm are not so rigid and the cutter does not cut them completely. To finish the job, lightly run a utility knife along the center of the groove and separate the pipe parts.

The cutter allows you to cut rings up to 1 cm wide and at the same time ensure a cutting accuracy of no more than 1-1.5 mm, which is quite acceptable in a practical sense.

Watch the video

Similar master classes