How to make a grinder attachment for an angle grinder

To convert an angle grinder into a grinder, a special attachment is sold. However, the cost of such equipment is almost the same as that of a full-fledged electric file with its own drive, so its purchase is impractical. Moreover, such an adapter has a simple enough design that you can make it yourself and much cheaper.

Assembling the grinder file should begin by making a drive roller for rotating the sanding belt. To do this, you need to press an extended M14 nut into a thick-walled steel pipe. It is unlikely that you will be able to find a tube of a suitable diameter, so you can take any available one, cut a 60 mm piece from it, spread it lengthwise to cut off the excess, then narrow it and weld it.

After obtaining the desired diameter, a nut is pressed into the pipe.

Next, the roller is screwed onto the angle grinder shaft.It is started and the pipe is ground in place to remove possible runout.

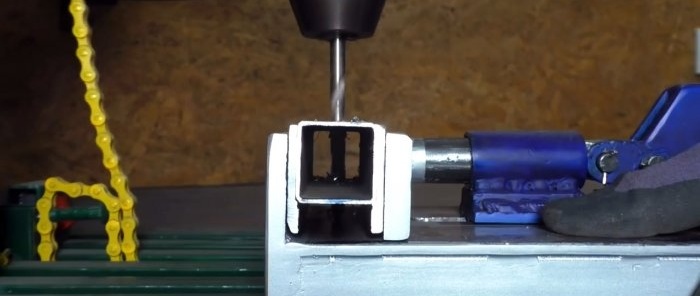

A base for mounting the adapter is cut out of sheet steel. To do this, you need to circle a glass or cup with an attached 50x50 mm profile pipe. In the center of the workpiece circle, a hole is drilled several millimeters larger in diameter than the angle grinder shaft.

A homemade clamp is welded to the resulting mount. It must fully correspond to the size of the clamp on the protective casing of the angle grinder.

Next, you need to weld a piece of pipe 50x50 mm 19.5 cm long to the fastening with a clamp. A window is cut out in it. Then the end of the pipe is welded with a square insert with a pin welded into it. The latter should extend a few centimeters from the other end of the pipe.

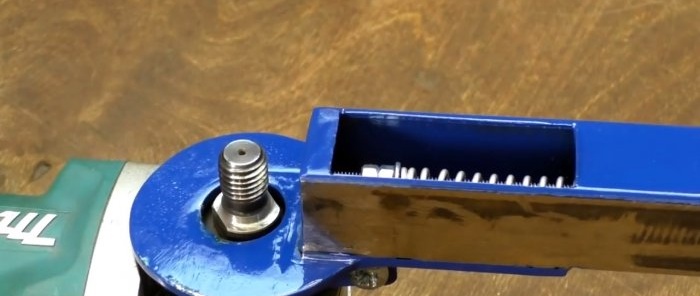

In a section of a 40x40 mm profile pipe 11.5 cm long, a through hole is made closer to the edge. Then the pipe is cut from the end to obtain eyes. A pin is passed through them, onto which nuts and 3 bearings are put on alternately. The result is a driven roller for the sanding belt.

The second end of the pipe with the driven roller is welded with a plug with a hole in the center. Then a twisted pressure spring is inserted into a large pipe with a pin, and after it a profile with a roller made of bearings.

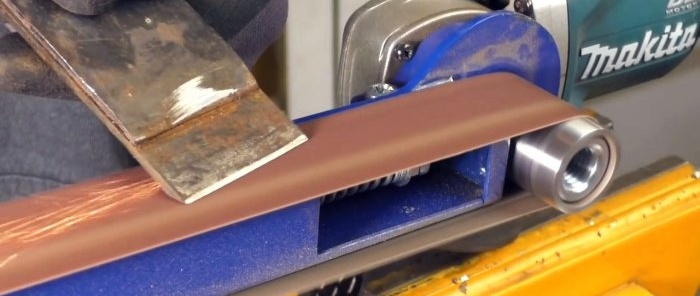

To install the adapter on an angle grinder, you need to clamp a large pipe onto it with a clamp instead of a protective casing. After this, the drive roller is screwed on and the sanding belt is put on. Due to the spring it receives tension. It can be adjusted by rotating the support nut on the stud through the window in the 50x50 mm pipe.

Materials:

- steel pipe with a diameter of 30-40 mm;

- extended nut M14

- sheet steel with a cross section of 3-4 mm;

- profile pipes 40x40x4 mm and 50x50x4 mm;

- M8 stud with nut;

- M8 washers – 4 pcs.;

- bearings – 3 pcs.;

- pressure spring;

- sanding belt.

Making the nozzle

Assembling the grinder file should begin by making a drive roller for rotating the sanding belt. To do this, you need to press an extended M14 nut into a thick-walled steel pipe. It is unlikely that you will be able to find a tube of a suitable diameter, so you can take any available one, cut a 60 mm piece from it, spread it lengthwise to cut off the excess, then narrow it and weld it.

After obtaining the desired diameter, a nut is pressed into the pipe.

Next, the roller is screwed onto the angle grinder shaft.It is started and the pipe is ground in place to remove possible runout.

A base for mounting the adapter is cut out of sheet steel. To do this, you need to circle a glass or cup with an attached 50x50 mm profile pipe. In the center of the workpiece circle, a hole is drilled several millimeters larger in diameter than the angle grinder shaft.

A homemade clamp is welded to the resulting mount. It must fully correspond to the size of the clamp on the protective casing of the angle grinder.

Next, you need to weld a piece of pipe 50x50 mm 19.5 cm long to the fastening with a clamp. A window is cut out in it. Then the end of the pipe is welded with a square insert with a pin welded into it. The latter should extend a few centimeters from the other end of the pipe.

In a section of a 40x40 mm profile pipe 11.5 cm long, a through hole is made closer to the edge. Then the pipe is cut from the end to obtain eyes. A pin is passed through them, onto which nuts and 3 bearings are put on alternately. The result is a driven roller for the sanding belt.

The second end of the pipe with the driven roller is welded with a plug with a hole in the center. Then a twisted pressure spring is inserted into a large pipe with a pin, and after it a profile with a roller made of bearings.

To install the adapter on an angle grinder, you need to clamp a large pipe onto it with a clamp instead of a protective casing. After this, the drive roller is screwed on and the sanding belt is put on. Due to the spring it receives tension. It can be adjusted by rotating the support nut on the stud through the window in the 50x50 mm pipe.

Watch the video

Similar master classes

How to make a belt grinder without welding on the base

The simplest grinder without welding and turning from a washing machine engine

Grinder from a washing machine engine

The simplest grinder without a lathe from a washing machine engine

How to make a super grinder yourself from an ordinary grinder

Simple 12V mini grinder

Particularly interesting

Comments (0)