You can take such a lightweight homemade wheelbarrow with you and store it anywhere

If you don’t have enough space to store a large purchased garden wheelbarrow, you can make it foldable with your own hands. So it will turn out even cheaper. Of course, you can’t use it for concrete, but it’s suitable for soil, leaves and sand.

Materials:

- wheel with bearings;

- threaded rod for the wheel axle;

- pipe;

- bolts, nuts, washers;

- tarpaulin.

The process of making a wheelbarrow

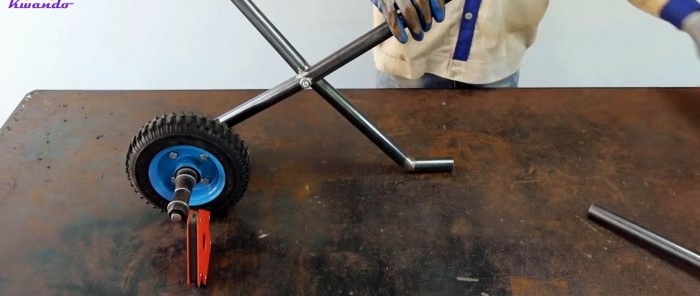

The first step is to assemble the wheelbase. A wheel is put on a 25 cm section of a hairpin. It is aligned in the center and pressed with nuts through washers. Bushings are put on the remaining part of the stud and also clamped.

Next, 2 pipes of 93 cm each are prepared. Marks are placed on them at a distance of 22 cm from the edge. You need to step back another 54 cm from them and put risks.

You need to cut wedges for bending pipes according to the marks. On marks of 54 cm, they are cut with a 90° offset relative to the first inserts. The pipes are bent, welded and cleaned. Be sure to check that the bends are the same.

Next, take 2 tubes of 87 cm each.Marks are placed on them 50 cm from the edge, then marks 28 cm from them. A wedge is also cut from them with the insert offset by 90°. The pipes are bent, welded and the seams are cleaned.

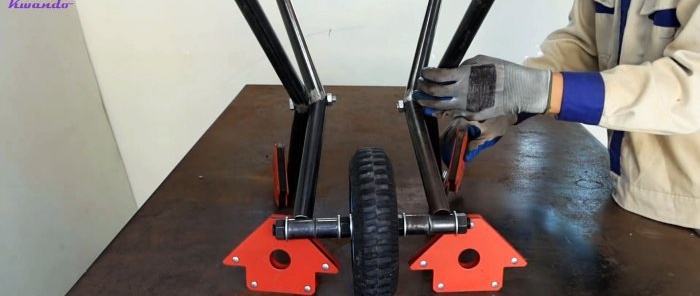

Now you need to tighten the pipes together crosswise with bolts. The first pair of pipes is drilled along the seam on the long bend, and the second on the short bend. The connected workpieces are tried on, resting against the bushings on the wheel axle. Wiring distances must be maintained. There is 25 cm between the crosshairs, 46 cm along the handles and the remaining edge.

To strengthen the structure, you need to make 2 crossbars from pipes 46 cm long. Their ends are rounded inward. Nuts are welded into them. The crossbars are then screwed through the previously made holes to the cross pieces at the bend of the beginning of the handles and the straight edge.

At the intersection of the pipes, a crossbar made of round timber 25 cm long is installed. The fastening bolts are welded to it at the edge at a right angle. It is inserted into holes on short cross tubes.

The resulting frame is welded to the bushings on the wheel axle. The open ends of the pipes must be welded immediately.

A pattern is made from tarpaulin or thick fabric and the body for the wheelbarrow is sewn together. When installing, the cover is threaded through the long crossbars; it is secured to the lower crossbar with straps.

Metal parts need to be painted and rubber linings on the handles. The resulting wheelbarrow can be folded, if there is very little storage space, it can even be disassembled into parts.

Watch the video

Similar master classes

How to make an injection propane burner from a piece of pipe

A convenient device made from a brake shoe for welding pipes under

How to make a light boat from PVC pipes in one evening

Drill stand for drill from old shock absorbers

This grinder machine cleans rusty pipes in no time

Do-it-yourself miter saw based on a grinder with a broach

Particularly interesting

How to install a socket if there are short wires left

How to eliminate gaps between the chimney and slate

How to mix an ultra-reliable solution for the oven that does not give

There will be no more cracks: What to add to concrete to make it

Never buy ball valves without checking with me

New technology for floor insulation with penoplex

Comments (0)