How to make a lightweight, razor-sharp kitchen knife that doesn't require sharpening

For cutting soft tomatoes, meat and other foods, it is better to use a very sharp knife. However, sharpening it takes a lot of time. In order not to constantly have to edit the knife, you can equip it with replaceable blades, replacing which takes a minute.

We cut out a blank from an aluminum strip in the shape of a blade.

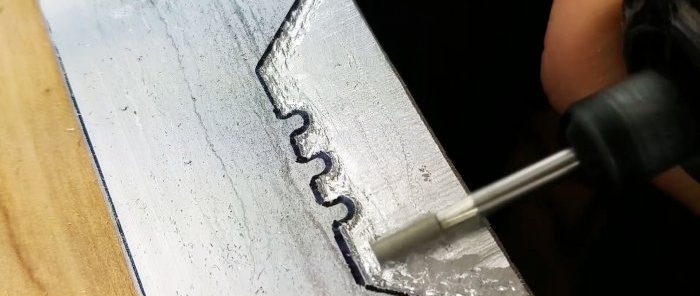

It is necessary to make a marking on it for 3 trapezoidal interchangeable blades, and select the metal using it using a drill. It is important that the cutting edges of the blades protrude from the aluminum base and the edges practically meet together.

On the smooth side of the workpiece, a bevel is made using sandpaper.

Next, it is drilled through the standard holes on the blades, then a thread is cut into it to screw them on.

The blades are screwed on.

The protruding part of the thread on the reverse is ground off.

The base itself needs to be polished. If there are scratches on it, then dirt will stick to it.

Finally, an overhead handle is made.

It can be secured with screws or rivets.

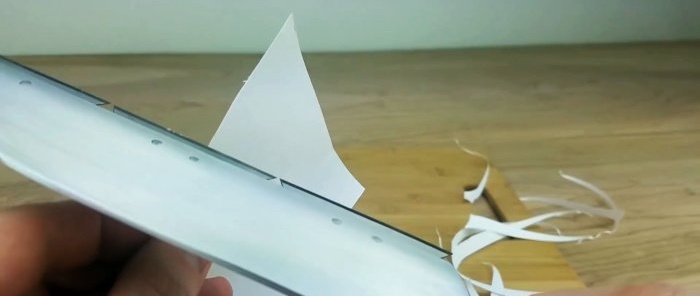

The resulting knife is ready for its intended use. In the future, when the sharpness is lost, its blades change.

Materials:

- aluminum strip;

- trapezoidal replaceable blades - 3 pcs.;

- M4 screws – 6 pcs.;

- blank for handle.

Knife making process

We cut out a blank from an aluminum strip in the shape of a blade.

It is necessary to make a marking on it for 3 trapezoidal interchangeable blades, and select the metal using it using a drill. It is important that the cutting edges of the blades protrude from the aluminum base and the edges practically meet together.

On the smooth side of the workpiece, a bevel is made using sandpaper.

Next, it is drilled through the standard holes on the blades, then a thread is cut into it to screw them on.

The blades are screwed on.

The protruding part of the thread on the reverse is ground off.

The base itself needs to be polished. If there are scratches on it, then dirt will stick to it.

Finally, an overhead handle is made.

It can be secured with screws or rivets.

The resulting knife is ready for its intended use. In the future, when the sharpness is lost, its blades change.

Watch the video

The information is provided for informational purposes only. The manufacture of bladed weapons is punishable by law.

Similar master classes

Sharpening and hardening the pencil sharpener blade

How to repair a kitchen knife with a broken tip (tip)

A tourist hatchet made from a rail without a forge, forging, etc.

How professionals sharpen and maintain scissors

How to make the simplest wind generator blades

How to make a knife from broken scissors

Particularly interesting

Comments (3)