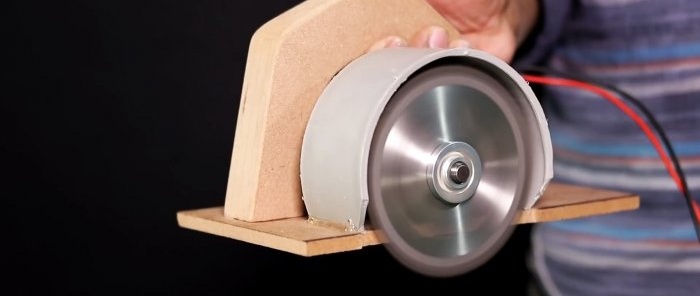

How to make a manual mini circular saw from cheap materials

You can use a mini circular saw to cut laminate, plywood and other thin sheet materials. To make it, you just need to buy an electric motor and a couple of little things. Despite the simplicity of this tool, it cuts like store-bought parquet.

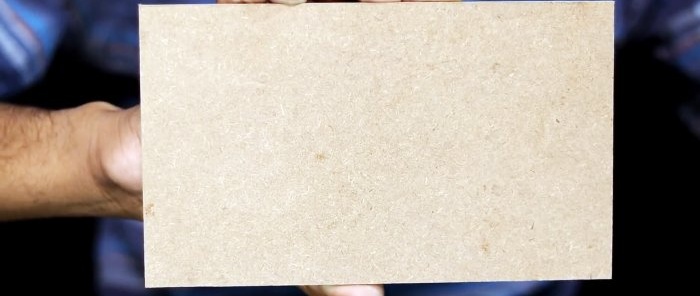

A 12.5x21 cm blank is cut out of MDF for the sole of the circular. Marks are placed along its long side 7 and 17.5 cm from the edge. Between them, the workpiece is ground 5 mm deep.

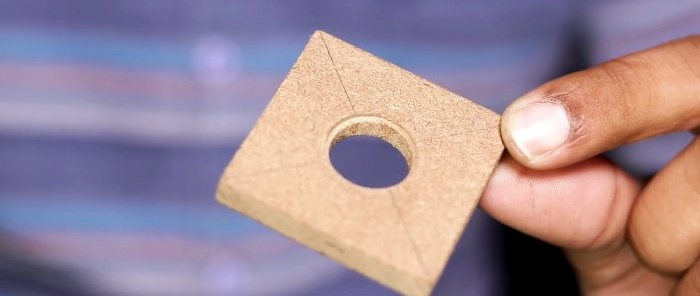

A 5x5 cm square is cut out of MDF. It needs to be drilled in the center for the motor shaft with a coupling, and on the side for the motor mount.

The workpiece is glued to the sole, and the engine is screwed to it.

A coupling is placed on its shaft.

Next, a casing for the saw blade is made. To do this, cut off a regular PVC pipe plug.

A hole with a diameter of 50 mm is sawn through it, then it is glued onto the sole.

To make a handle for a circular saw, you need to glue 4 pieces of MDF and cut it out of them.

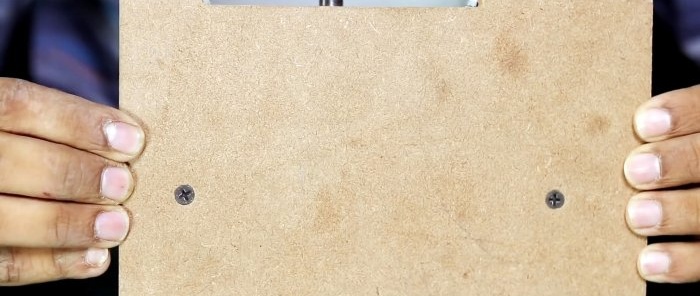

It is screwed to the sole with self-tapping screws.

There is a push button embedded in the handle.

Next, the wires are soldered through it to the engine.

They are connected to a power supply or battery. A disk is installed on the coupling.

Now, when you press the button, the circular saw will cut.

Using the same technology, you can make a mini table saw - https://home.washerhouse.com/en/6098-izgotovlenie-nastolnoj-mini-pily-12-v.html

Materials:

- electric motor 895 -

- MDF 8 mm;

- coupling on the motor shaft -

- PVC plug for pipe 110 mm;

- push button;

- saw blade for wood 85-100 mm.

Circular manufacturing process

A 12.5x21 cm blank is cut out of MDF for the sole of the circular. Marks are placed along its long side 7 and 17.5 cm from the edge. Between them, the workpiece is ground 5 mm deep.

A 5x5 cm square is cut out of MDF. It needs to be drilled in the center for the motor shaft with a coupling, and on the side for the motor mount.

The workpiece is glued to the sole, and the engine is screwed to it.

A coupling is placed on its shaft.

Next, a casing for the saw blade is made. To do this, cut off a regular PVC pipe plug.

A hole with a diameter of 50 mm is sawn through it, then it is glued onto the sole.

To make a handle for a circular saw, you need to glue 4 pieces of MDF and cut it out of them.

It is screwed to the sole with self-tapping screws.

There is a push button embedded in the handle.

Next, the wires are soldered through it to the engine.

They are connected to a power supply or battery. A disk is installed on the coupling.

Now, when you press the button, the circular saw will cut.

Using the same technology, you can make a mini table saw - https://home.washerhouse.com/en/6098-izgotovlenie-nastolnoj-mini-pily-12-v.html

Watch the video

Similar master classes

Particularly interesting

Comments (0)