How to make a device and make hinged hinges with your own hands in no time

In some cases, in a household or country house, expensive factory-made hinges can be successfully replaced with homemade ones. Moreover, this does not require valuable materials and high qualifications of the performer.

Will need

Materials:

- tool steel Kh12MF or Kh12F1;

- sheet steel 1.6 mm thick;

- nails with a diameter of 3 mm;

- lubricant

Tools: drilling machine (drill), circular saw (band saw, milling machine, grinder, hacksaw), needle file, screw press (vice), grinder, metal scissors, file, etc.

The process of making a matrix for forming hinge hinges and the canopies themselves

We focus on available material. If it changes, then the calculations will have to be adjusted. We also provide a list of tools to use in the upcoming task. Their choice is unprincipled.

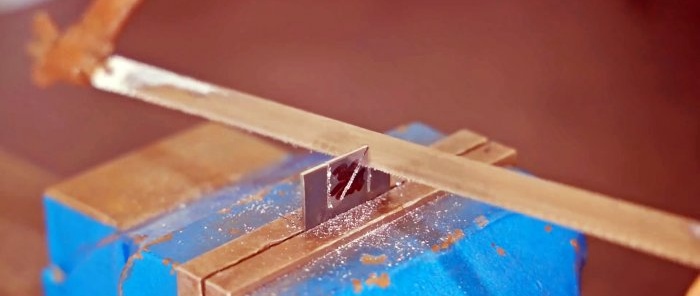

In a rectangular beam made of tool steel X12MF or X12F1, we make a through hole to form hinge hinges. Therefore, based on the available material, we calculate its diameter.It must be greater than the sum of twice the thickness of the material for the hinges (1.6 × 2 = 3.2 mm) and the axial pin (nail) with a diameter of 3 mm, i.e. 6.2 mm. To prevent the hinge from jamming, we drill a hole with a diameter of 7 mm.

High-quality and durable drills on AliExpress at a discount - http://alii.pub/5zwmxz

Across the entire width of the beam we make a vertical slot of 1.5 mm tangential to the hole. Using a 1.6 mm thick strip of metal instead of a template, we use a file to bring the slot width to +1.6 mm.

We separate the fragment with the hole and slot (matrix) from the rest of the beam, remove the burrs and round the outer edges.

Let's start by making simple loops made from individual cards.

We bend one edge of the plate with a hammer to facilitate bending of the metal in the matrix, lubricate the end of the plate with oil and press on it from above with a screw press or the jaws of a vice.

To obtain a round hinge, insert a nail into the matrix. We press on the plate until the bent end, having completed almost a revolution in the matrix, rests against the vertical section of the plate.

We knock out the nail from the hinge and drill it out to 3.2 mm.

We place the plates with hinges on the nail and check the freedom of rotation.

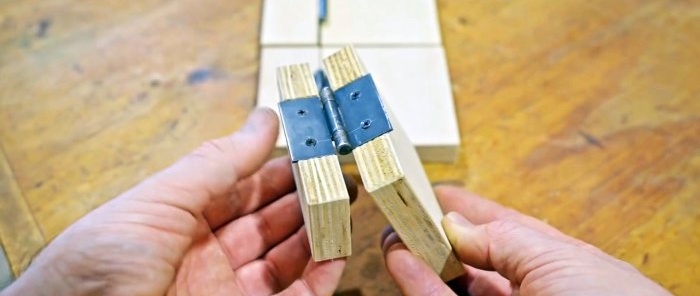

Let's make more complex loops - overhead and butterfly loops. To do this, we cut 4 identical blanks from a strip of sheet metal, mark and drill holes for fastening, and also make cuts and protrusions using various tools.

Next, we perform the same operations as when testing the matrix. But, since the wings of the loops are connected together, we additionally make a fine adjustment using a file.

We combine the hinges of the hinge wings and connect them with an axial pin (in our case, a nail) with a diameter of 3 mm.We bite off the protruding ends of the pin with scissors and cutters and shorten them on the grinder.

To prevent the pin from falling out, flatten the ends with a hammer.

We do the same thing when making a butterfly loop, except for the shape of the cards.

Using the hinges we made, we successfully hang the door panels to the jamb and the result will be no worse than with factory-made products.