How to make a heated desoldering pump for convenient desoldering of circuit boards into parts

To desolder the attached components from the board, you have to tinker, since it is difficult to simultaneously melt the solder on all the legs and remove the desired part. For this purpose, a desoldering pump is used to remove the solder from the individual legs, releasing them. This device is a godsend for a radio amateur, but it can work even better if it is modified a little.

Materials:

- Manual desalination pump - http://alii.pub/67pvf8

- heat-insulating sleeve;

- blank for turning;

- transformer 12 V 3-4 A or power supply - http://alii.pub/67pvgl

- nichrome wire.

Manufacturing process of electric tin pump

The device is manufactured on the basis of a manual desalination pump.

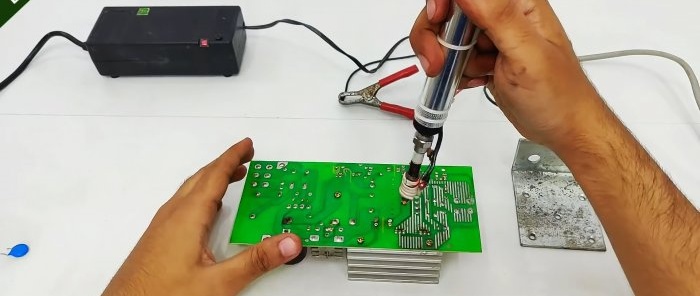

It was originally designed to remove already liquid molten solder, which is not entirely convenient. To improve the design, it is necessary for the device to melt the tin itself and then remove it. To do this, you need to turn a steel tip on a lathe for a manual desoldering pump.

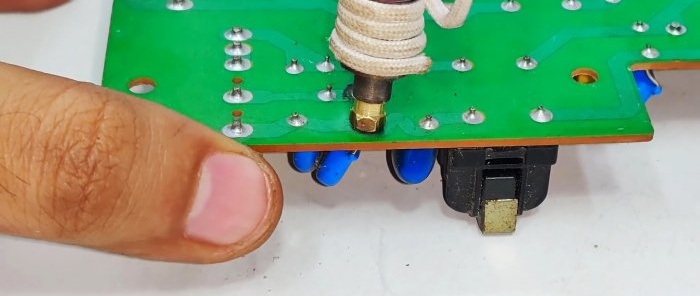

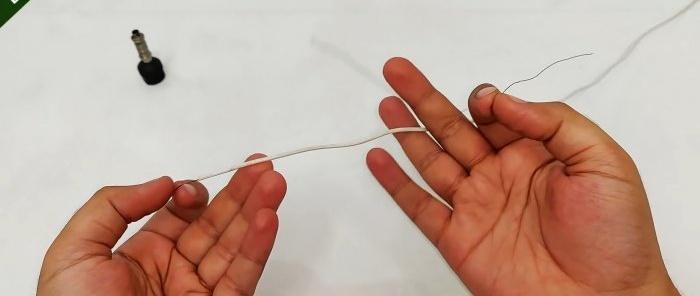

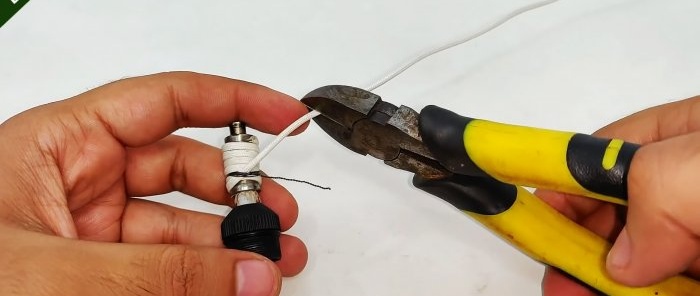

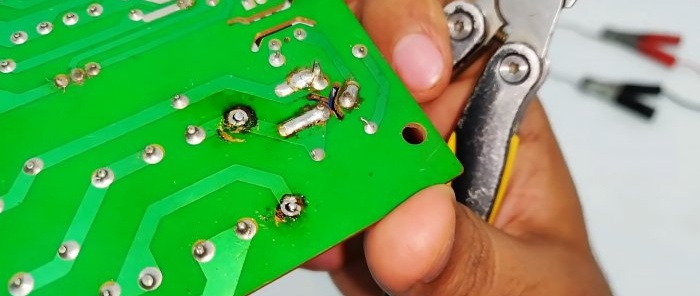

Then we put a heat-insulating high-temperature sleeve on the nozzle, and pull the tip on top. After this, you need to wrap a nichrome wire placed in temperature-resistant insulation around the tip.You can secure it at the beginning of the winding with ordinary heat-resistant wire.

The device assembled in this way works great, but problems may arise with heating of the plastic parts of the desoldering pump. In this case, you will need to move the hot tip away from the nozzle using various tubes and adapters that you can find. You can also put a brass attachment on the steel tip, which will make working with the device more comfortable.

The wound heating thread is twisted with wires from a 12 V power source. The wires themselves can be secured to the desoldering pump with ties. Now if you apply voltage, the tip will heat up. By leaning it against the leg of the part on the microcircuit, we melt the solder, and by pressing the piston button of a manual tin pump we remove the tin.

Watch the video

Similar master classes