7 expert tricks to work faster

The same things can be done in different ways. Some methods are slow, others are much faster. This collection contains practical ideas that allow you to quickly solve various problems that you encounter in the workshop.

1. Clamp for drilling machine

To fix workpieces on the work table of a drilling machine, you can make a simple but powerful clamp. To do this, we prepare a piece of corner slightly longer than the distance between the grooves on the machine’s work table. The corner is applied to the table and drilled on the corner exactly opposite the grooves.

We insert the bolts into the grooves from the side and put the corner on them. To press it, we make handle-nuts from wooden circles.

After this, the clamp is ready for use.

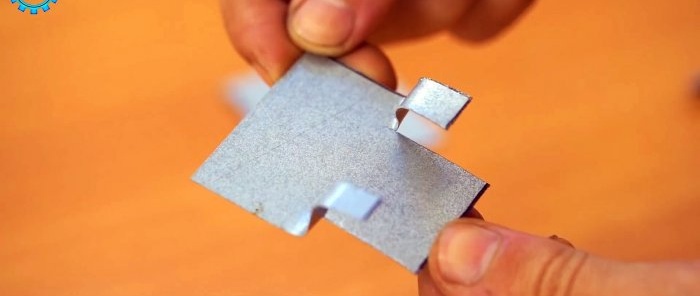

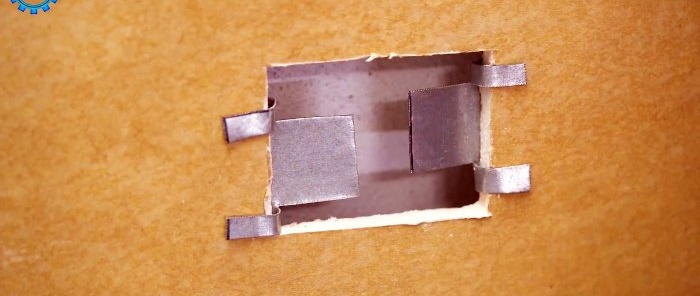

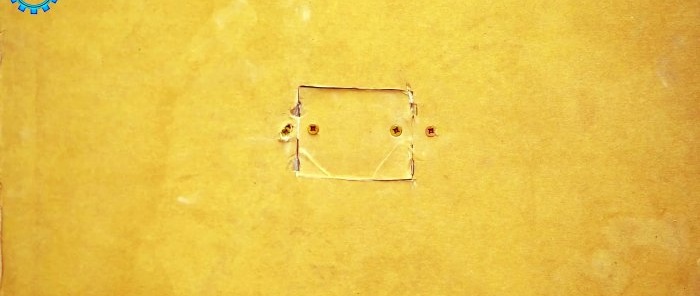

2. How to close a large hole in drywall

If there is a large hole in the drywall that needs to be sealed flush, then an insert is cut to fit it. To secure it, 2 brackets are made of tin or sheet aluminum. First, 2 plates are cut out, along the edges of which antennae are made as in the photo.It turns out that on the reverse side the insert rests on the plates, and on the front side it is held in place by folded tendrils.

We install the staples in the hole and bend the antennae so that they do not fall.

This allows you to screw them to the drywall and secure the insert. Then the antennae break off.

3. Splicing of PP pipes without a coupling

PP pipes can be spliced without a coupling. To do this, it is necessary to prepare a piece of rod 50-80 mm long, the same in cross-section as the internal diameter of the pipe. It is used as an insert to connect 2 pipes. They are joined, but leaving a gap of 10 mm.

Using a heat gun, heat the edges of the pipes and then join them tightly. After this, while the polypropylene is hot, the joint is rolled over a flat base. As a result, the pipes will be soldered together, and the insert can be knocked out. This connection turns out to be very strong and cannot be broken.

4. Soft pads on the vice

To prevent the hard jaws of the vice from leaving dents on the workpiece, you can put soft pads on them. Those are made from foamed pipe insulation. You just need to cut it lengthwise and put it on your lips.

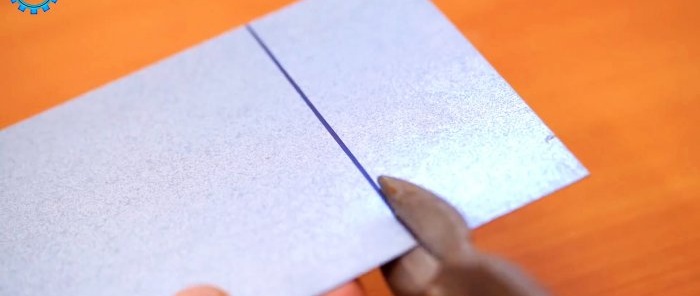

5. How to install a blind rivet if the gun does not pull it

It happens that you come across blind rivets with a thin shaft that the jaws of the gun do not grip, or the tool itself is simply worn out and does not work. In this case, the rivet can be riveted with a hammer, and the rod can be bitten off with wire cutters.

This installation method, if necessary, allows for a not too tight clamping between the parts, which may be required if they must rotate relative to each other.

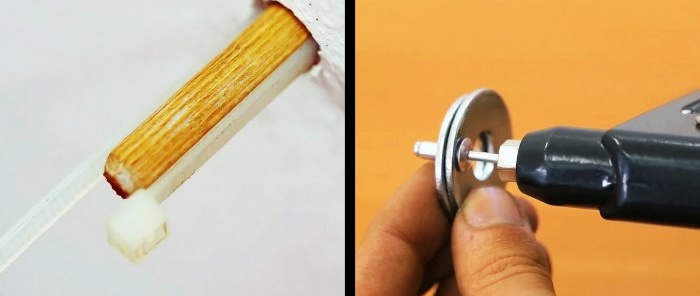

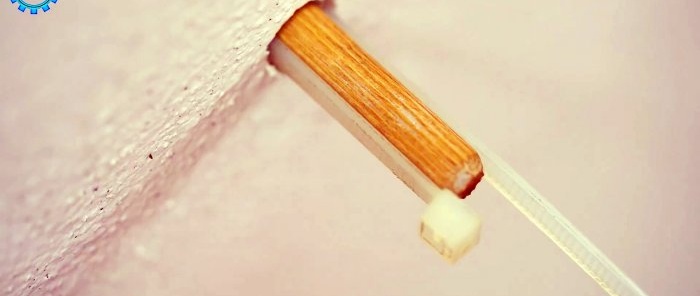

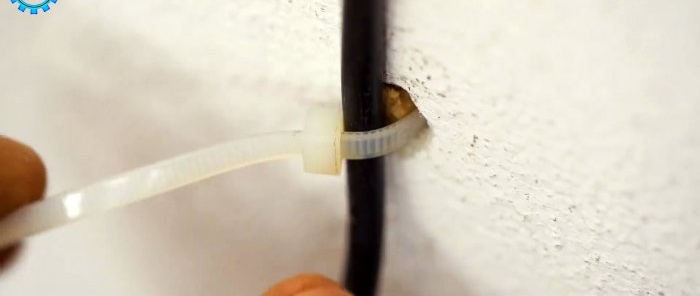

6. Fastening the cable to the wall with nylon ties and dowels

To attach the cable to the wall, you can drill a hole in it and drive a dowel into it with a nylon tie bent in half.Due to this, it will fit tightly. The protruding edges of the tie will allow you to tighten the cable.

7. How to make threads on polypropylene pipes

On PP pipes, it is better not to cut the threads, but to melt them. To do this, we heat any metal fitting with the required thread, and while it is hot, screw it onto or into the pipe.

After this, wait a couple of seconds for the polypropylene to harden, and unscrew it back. In the end, all that remains is to trim the sagging at the end of the pipe.

Watch the video

Similar master classes

Particularly interesting