Do-it-yourself grinding thicknesser attachment for a drilling machine

To bring wood blanks to perfection, you can attach a sanding thicknesser to the drilling machine. It is cheap to make and quite simple, but very useful. If you have a drill press, then be sure to make this attachment for it.

Materials:

- Plywood or chipboard;

- furniture pins – 2 pcs.;

- wood glue;

- door hinges – 2 pcs.

- mounting bracket;

- sandpaper;

- M10 pin;

- bearing with an inner race diameter of 10 mm;

- bolts, nuts, washers, screws.

The console manufacturing process

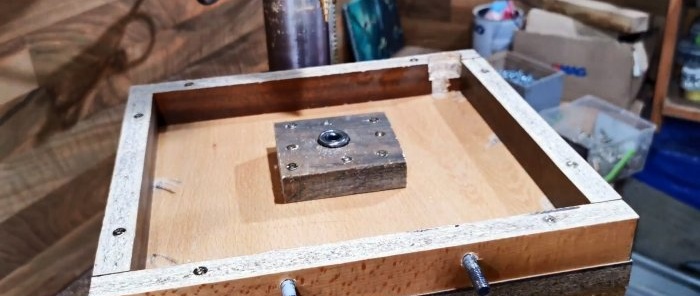

The bottom of the attachment is made from chipboard or plywood, slightly larger in size than the drilling table of the machine.

In alternation, slats are screwed to it on three sides. The drill table needs to fit right between them. It is required that a pair of slats extend beyond the bottom by 6-10 cm.

Using a crown, you need to drill out discs from the same material and glue them together to get a grinding drum. To do this, they are tightened with a hairpin.

Walls made of slats are screwed onto the previously made bottom from the reverse side around the perimeter.

Then a lid with one side wall is made under it.

With its help, it should be pressed against the base; for this, 2 furniture pins are screwed into it.

Next, you can use the adjustable support to adjust the grinding depth. It is a board made of chipboard, which is screwed to an L-shaped rack made of the same material using furniture hinges. The stand is screwed onto a rail protruding beyond the base. It is necessary to install a mounting bracket on the support itself.

An arc-shaped groove is milled into the base cover, along which the position of the support can be fixed by clamping the mounting angle.

In the center it is drilled under the drum.

The mortgage is secured at the bottom of the base with self-tapping screws. It needs to be drilled and the bearing pressed into the hole. This will allow you to hold the drum shaft from below.

The base is visible from the side, and a pipe from a sewer pipe is glued into this hole. It is needed to connect a vacuum cleaner to the console, thereby collecting sawdust during operation.

To adjust the position of the support, you need to make a slider that will slide in the arcuate groove. It is assembled on the basis of a mounting plate with three holes. A long bolt is screwed into the central one, and short ones with bushings to match the width of the groove into the outer ones. It is then screwed to the mounting bracket on the support.

The sanding drum is being ground. After this, you need to stick sandpaper on it.

Thus, this attachment allows workpieces to be passed between the retaining wall and the grinding drum. As a result, they become smooth and acquire the correct plane.

Watch the video

Similar master classes