One high-quality welding technique from the pros

In order to perform a high-quality weld, it is necessary to take into account many different factors: the configuration, in particular, the thickness of the workpieces being welded, the welding equipment used, the type and diameter of the electrodes used, the strength of the welding current, etc.

But there is another factor that is not fully mastered by a welder without much experience, but is well known to an experienced specialist, and he successfully and regularly uses it. We are talking about transverse oscillatory movements of the electrode along a certain trajectory, performed with a constant frequency and amplitude, and coordinated with longitudinal movement along the welding seam.

To demonstrate the work of a novice and an experienced welder, we will take a metal rod and a flat metal surface as the parts to be joined. This is similar to welding round door hinges to the jamb and door leaf. We will use manual arc welding and coated electrodes brand E6013 diameter 2.6 mm.

How does an inexperienced welder act?

We make sure that he already knows about the safety rules and sanitary standards of this profession, since he is wearing the appropriate equipment - canvas trousers and a jacket, leather shoes, special gloves and a mask with a light filter.

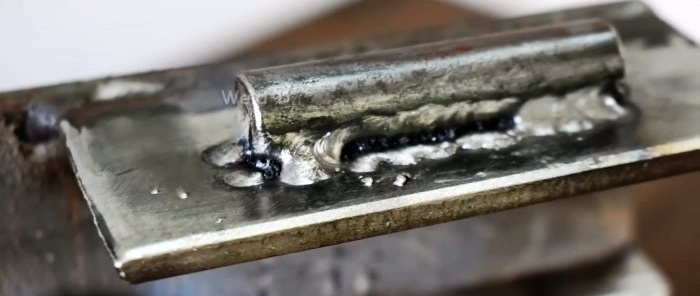

It sets the welding current to 75 A, which is slightly less than what would be needed for this welding process. He grabs a metal rod laid on a flat surface at the ends and begins to apply a seam in the longitudinal direction to obtain a permanent connection of two parts.

His plan is to apply the suture with one continuous longitudinal movement of the electrode from start to finish, and at first glance he does this quite well. But having beaten off the slag, we are convinced that the seam contains slag inclusions in the form of a longitudinal strip and individual points, which were formed due to lack of space and the trajectory of the electrode, which prevented the slag from coming out.

How an experienced welder works

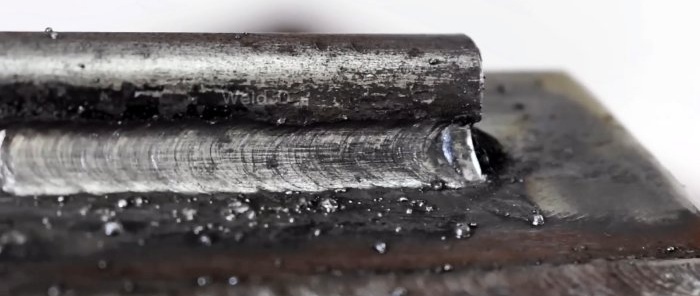

Taking into account the thickness of the parts, it increases the welding current to 95 A and reduces the angle of electrode in relation to a flat part and plans to make zigzag transverse movements with the end of the electrode between the parts being connected. Then he masterfully translates his plans into reality. After beating off the slag, we see a continuous dense welding seam, uniform in height and width, without slag inclusions.

Welding electrodes for general purposes on AliExpress at a discount - http://alii.pub/606j2h

Watch the video

Gasless semi-automatic 3 in 1 or how to forget about cylinders, electrodes and slag with a Chinese novelty - https://home.washerhouse.com/en/7364-bezgazovyj-poluavtomat-3-v-1-ili-kak-zabyt-pro-ballony-jelektrody-i-shlak-s-kitajskoj-novinkoj.html

Similar master classes