How to make a latch for a carriage-type door from leftover metal

Factory latches are not always suitable for gates or utility room doors due to the non-standard nature of the latter, and they cost a lot of money. For these purposes, you can make a simple design, quite original and reliable door latch from scrap metal. And this does not require special knowledge, skills or costs. Almost any adult can handle this type of work with sufficient care and persistence.

Will need

Materials:

- sheet metal circle;

- welded hinge for metal doors;

- a piece of round steel pipe with a diameter of 48 mm;

- hex bolt;

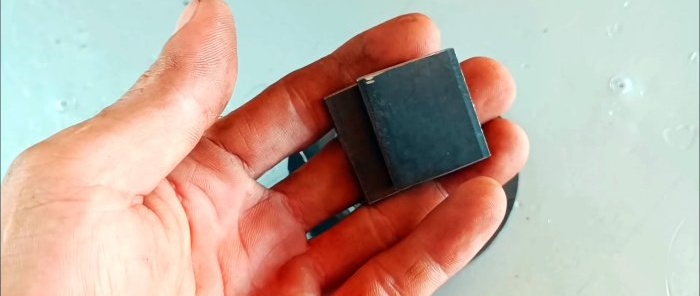

- 2 rectangular plates 28x32 mm;

- rivets.

Tools: metal ruler, marker, vice, grinder, pliers, core, drill, welding machine, riveter.

The process of making a simple and reliable door latch from waste materials

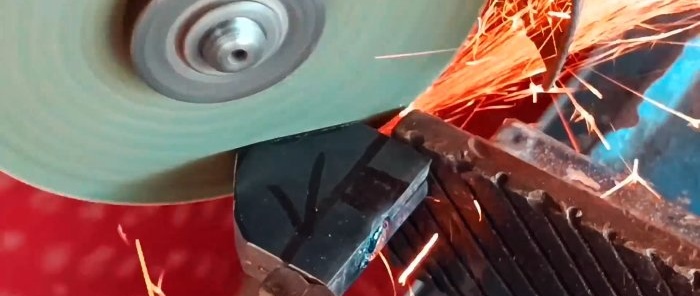

We cut a ring from a fragment of a round pipe with a height equal to the thickness of the circle cut from sheet metal. We also shorten the upper part of the welded loop by a certain amount.

Find the center of the metal circle and drill through hole for hex bolt. We drill a hole in the shortened upper part of the welded loop for it.

A previously cut ring from a pipe weld coaxial to the circle. From the side of the welded ring, insert a bolt into the hole of the circle with the shortened upper part of the welded loop pre-attached to it and cut off the bolt shaft on the reverse side is just below the surface of the circle.

We round the hexagonal head of the bolt using a drill and grinder. From two plates measuring 28x32 mm, there are shaped parts with a slot on the flat side equal to the height of the ring welded to the circle.

Insert a shortened bolt with a rounded head into the hole of the circle from the side of the welded ring. We place two shaped parts with slots on the ring on two sides of the shortened upper welded loop in opposite directions and weld To her.

Metal circle with welded ring cut along the chord so that the central hole is completely on most of the circle, into which we insert a shortened bolt with part of the loop from the side of the welded ring and weld the bolt rod to part of the circle.

In parts of a circle around the circumference drill out 3 holes each for attaching them to the door. We attach the smaller part of the circle to the door frame using rivets so that the cutting line coincides with the inner edge of the frame.

We press the larger part of the circle along the cutting line to the smaller one and fasten it to the door leaf with rivets. When the curly handle parts are in a vertical position, the door leaf can be opened or closed. If they are installed horizontally, the door leaf is closed.

Watch the video

Similar master classes