How to make a smart deadbolt lock from trash

For the doors of outbuildings in a country house or farmstead, it is not necessary to spend money and buy factory-made locking products. If you have basic plumbing skills, you can make them yourself from waste materials and almost without spending money. This deadbolt lock can be called “smart”, since it cannot be opened through a slot like a regular deadbolt, since its running gear rests against the handle. The second point is that thanks to the use of a lever handle, the deadbolt is very easy to open and close without any extra effort.

Will need

- Ruler and marker;

- two square rods of different sections;

- steel strips of different widths;

- round rod;

- carbine;

- screws, etc.

The manufacturing process of a smart deadbolt lock

From a square rod obtained by forging (it is stronger), we cut out a piece of the required length. We bend one end of the steel strip at 90 degrees according to the markings, using a vice and a hammer.

From another strip we bend 3 two-legged brackets of the same size, two of which will be guides, and one will be a counter part into which the crossbar will fit in the closed position.

We install these three parts on a steel strip in the places intended for them, mark on the strip a line for cutting and installing staples, as well as marks for drilling countersink holes.

We weld two brackets next to a small gap, and one at some distance to the steel strip.

We insert the rod (crossbar) into the brackets so that its end comes out on the opposite side of the paired loops and mark the place where it is cut not far from the inner paired loop.

We bend the strip in a U-shape, cut the legs to size and weld them into the gap between the parts of the crossbar.

We bend the end of the tetrahedron of the smaller section at an angle of 90 degrees and above it we bend the larger side at a small angle in the opposite direction, departing from the right angle by about 1/3 of its length, in the same plane in which the right angle lies.

To the end of the short side of the tetrahedron, transverse to the plane of bends, we weld a short round rod, the height of which should be slightly greater than the height of the U-shaped strip.

We drill a hole in the center of the bend of the tetrahedron at a right angle parallel to the round rod.

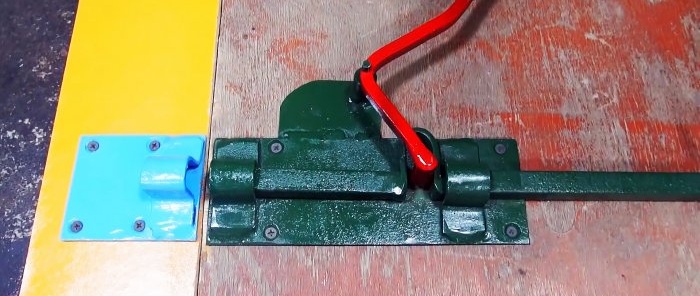

We install the crossbar in the closed position and immediately behind the U-shaped bracket, to the strip to which the three brackets are welded, we weld a steel plate with rounded outer corners.

To the rounded corner of the plate closest to the U-shaped bracket, we vertically weld a round bead with a machined upper part, onto which we put a tetrahedron-handle bent in two places along the hole.

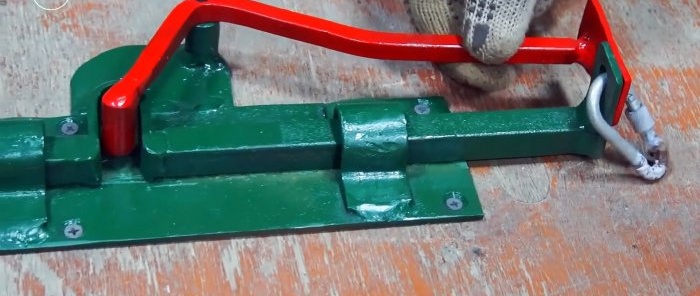

We weld a plate with a hole vertically to the outer end of the long part of the crossbar.We install the tetrahedron-handle in the closed position, shorten it if necessary and weld, but horizontally, a plate with a hole.

In the closed position, the holes of the plates must match so that they can be secured with a carabiner.

We cut off part of the plate from the outer of the two paired two brackets.

We fasten the part of the lock with the bolt to the door frame with screws, and the single bracket to the door leaf opposite or vice versa, depending on which option is more convenient to implement and ensures the greatest reliability.

To prevent the door from opening, the handle and bolt plates can be secured with a steel carabiner.

Watch the video

Similar master classes